Description

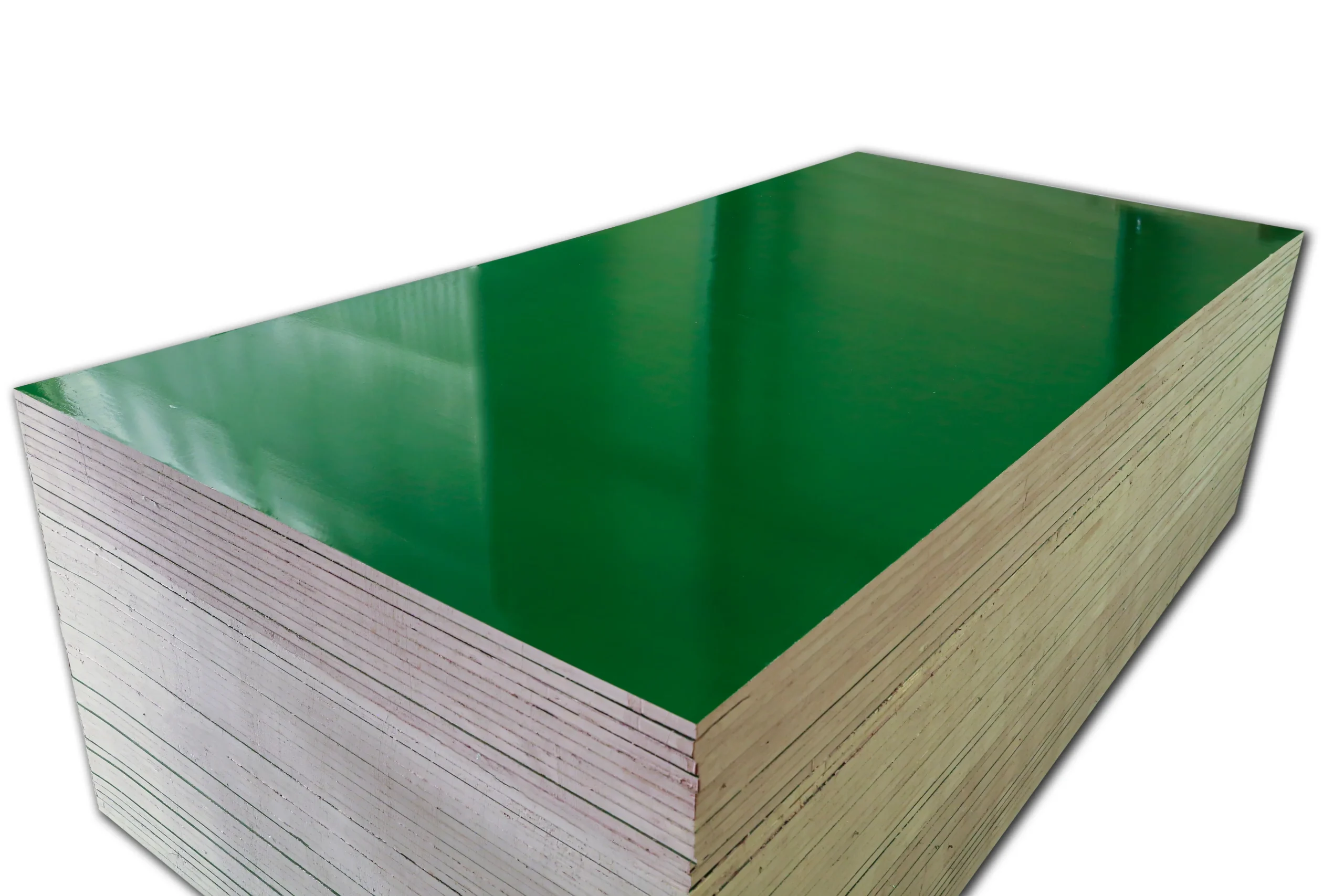

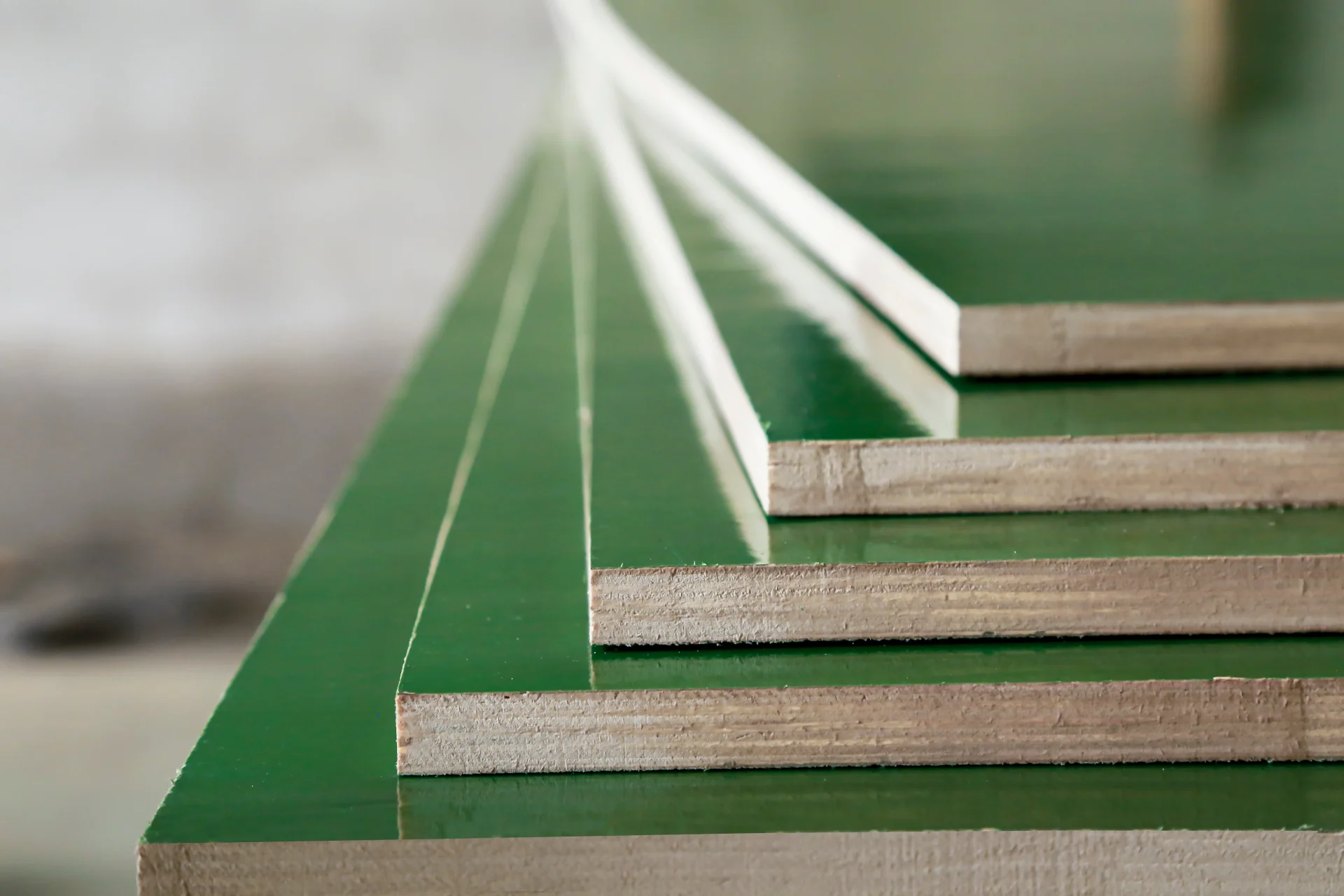

Durable Waterproof Plastic Film Faced Plywood is a new type of film-facing laminate. Its base material is particle board and medium fiber board, which are made by bonding the base material and the surface. The surface veneers are mainly domestic and imported, because they are fireproof, abrasion-resistant, and waterproof. In the production of all poplar plywood, each sheet is selected and repaired and used after secondary molding.

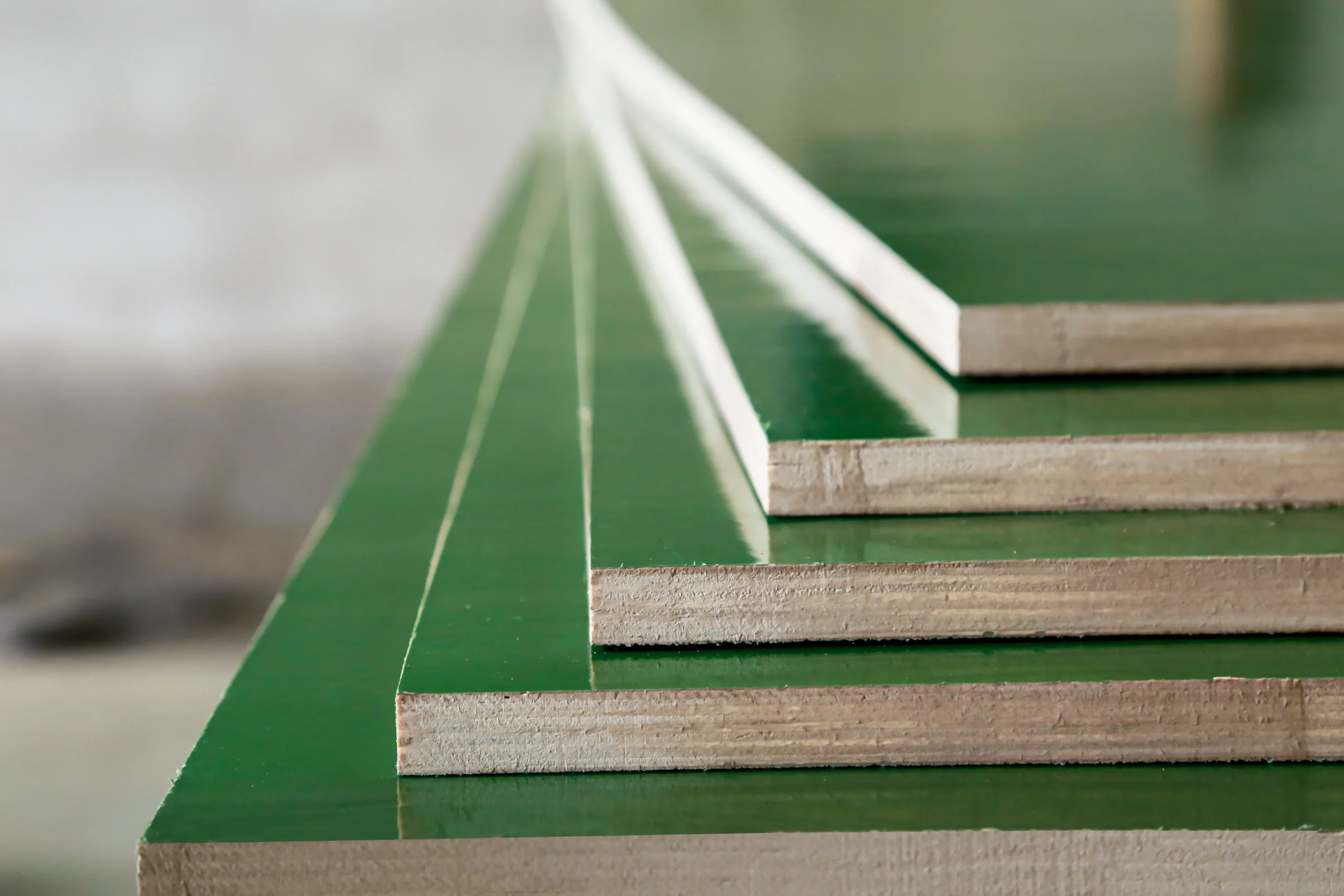

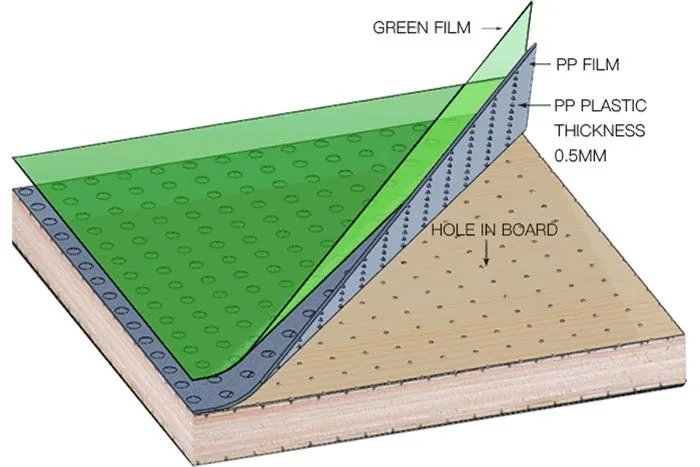

Compared with traditional laminated paper plywood, Durable Water Proof Plastic Film Faced Plywood uses pp plastic wear-resistant film on high-quality veneer.

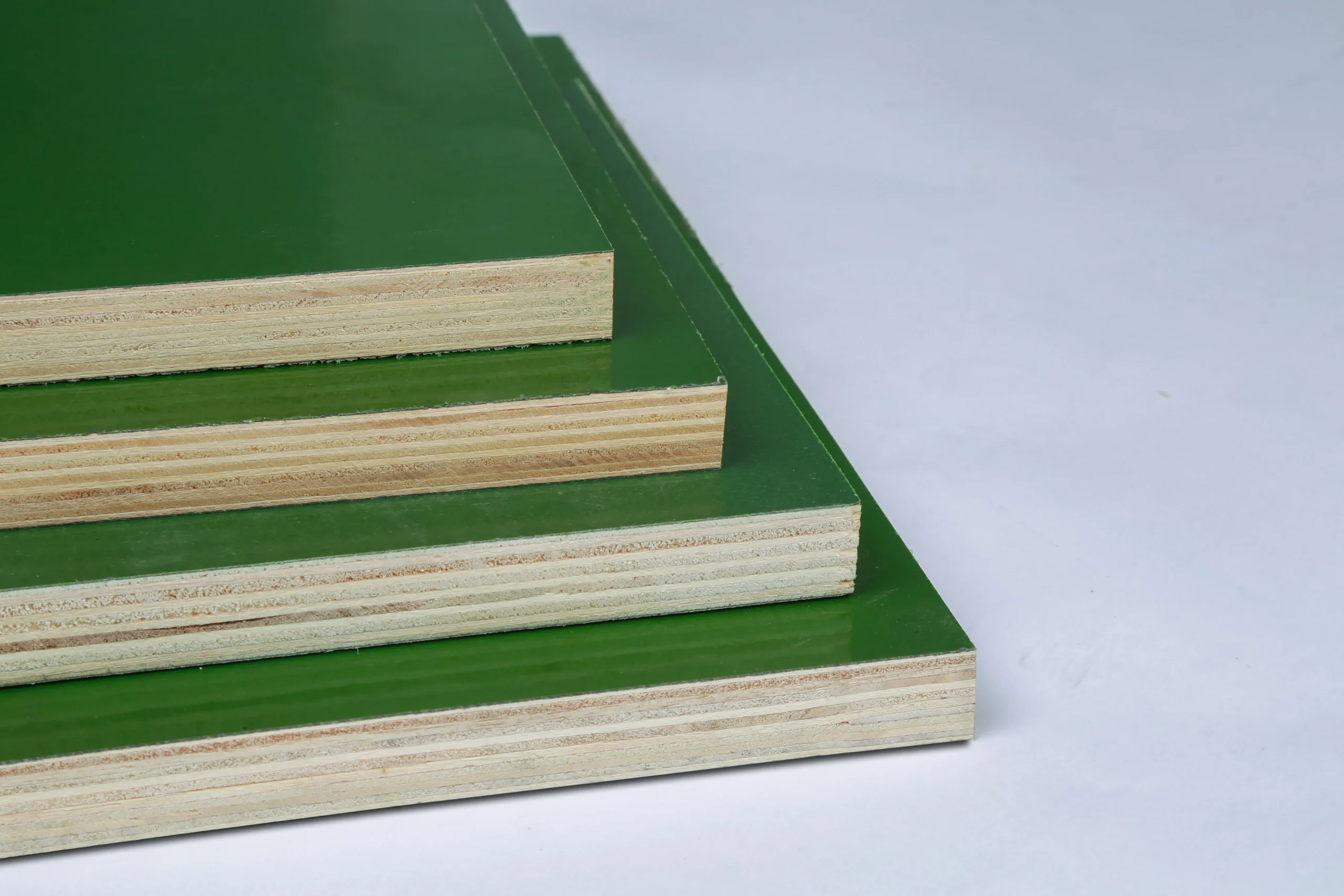

Compared with traditional laminated paper plywood, Durable Water Proof Plastic Film Faced Plywood uses pp plastic wear-resistant film on high-quality veneer. It is easy to demould, does not contain a release agent, does not stick to cement, and the concrete surface is very smooth. It has more reuse times than ordinary laminated plywood. It has perfect waterproof performance and wear resistance. Glue makes it stronger and increases the reuse time to 20-30 times. Durable Water Proof Plastic Film Faced Plywood is easy to transfer to the concrete build. It is waterproof, wear-resistant, crack-resistant and environmentally friendly. It is sealed with waterproof paint, and the color can be customized. It is used in real estate construction and formwork panels. It has stronger impact strength and high processability.

The advantages of durable waterproof plastic film-faced plywood are also obvious, such as good bonding strength, no glue, no break, waterproof, anti-corrosion, etc. When in use, the surface should be relatively smooth, with good flatness, and no carbonization, and the overall thickness of the board should be relatively uniform. Since waterproof glue and phenolic glue are used for bonding in production, the bonding strength is very high and can be greatly adapted to different usage scenarios.

PP Plastic Film Faced Plywood is a new type of film faced laminate. Compared with traditional film faced laminates, it has the following advantages:

- Easy to demould, release agent free, nonstick cement, concrete surface is very smooth.

- More reuse times than normal film faced plywood.

- Waterproof performance is perfect and wear resistant

Detail

Production Process

RAW MATERIALS STORAGE

We have several warehouses to store all our Raw Materials like Poplar Veneer, Hardwood Veneer, Sapelli/Bintangor/Okoume/Pencil Cedar/Pine Face/Back, etc. Once new raw materials delivered into our warehouses, our workers will inspect all and place different grade ram materials into different warehouses.

RAW MATERIALS PRETREATMENT

Once production started, our workers will pretreat the raw materials including the sides joint, gluing.

VENEERS ASSEMBLE

Our workers will assemble the wood veneers one layer by one layer on the assembly line. Like the 18MM will consist of 11 layers wood veneers.

RAW BOARDS PREPRESS

After Veneer Assemble Process, all the Raw Boards need to be prepressed by Cold Press Machine. So that the Raw Boards can be shaped into Raw Plywood. This process need at least 2 hours.

RAW PYWOOD HOT PRESS

Shaped Raw Plywood will be laminated by Hot Press Machine. This process need at least 1 hour. After Hot Press, the Raw Plywood bonding will be strong.

RAW PYWOOD REPATCHING & PUTTYING

This process is to fill the gap on the surface of raw plywood.

RAW PYWOOD SANDING

Put the Raw Plywood into Sanding Machine. After sanding, the raw plywood surface become smooth, and thickness will be even also.

FACE/BACK VENEER ASSEMBLE

Raw Plywood will be glued firstly. Then workers will place the face/back veneer like Sapelli /Bintangor/Okoume/Pencil Cedar on the both sides of raw plywood.

COLD PRESS

After Face/Back Veneer Assemble Process, plywood will be placed into Cold Press Machine again. So that the Face/Back Veneer will bond with the raw plywood initialy. This process need at least 1 hour.

LAMINATED PYWOOD HOT PRESS

This process need at least 30 minutes. After second Hot Press, Face/Back Veneer will bond with the raw plywood strong.

CUTTING & POLISHING

All plywood will be cut into standard size like1220X2440MM. Then plywood will be polished gain to make the face/back smooth.

INSPECTION & PACKING

Inspect boards for defects (e.g., cracks, uneven density, surface imperfections). Grade the qualified boards based on quality standards. Stack and package the boards for storage or shipment.

Quality Control & Packing