说明

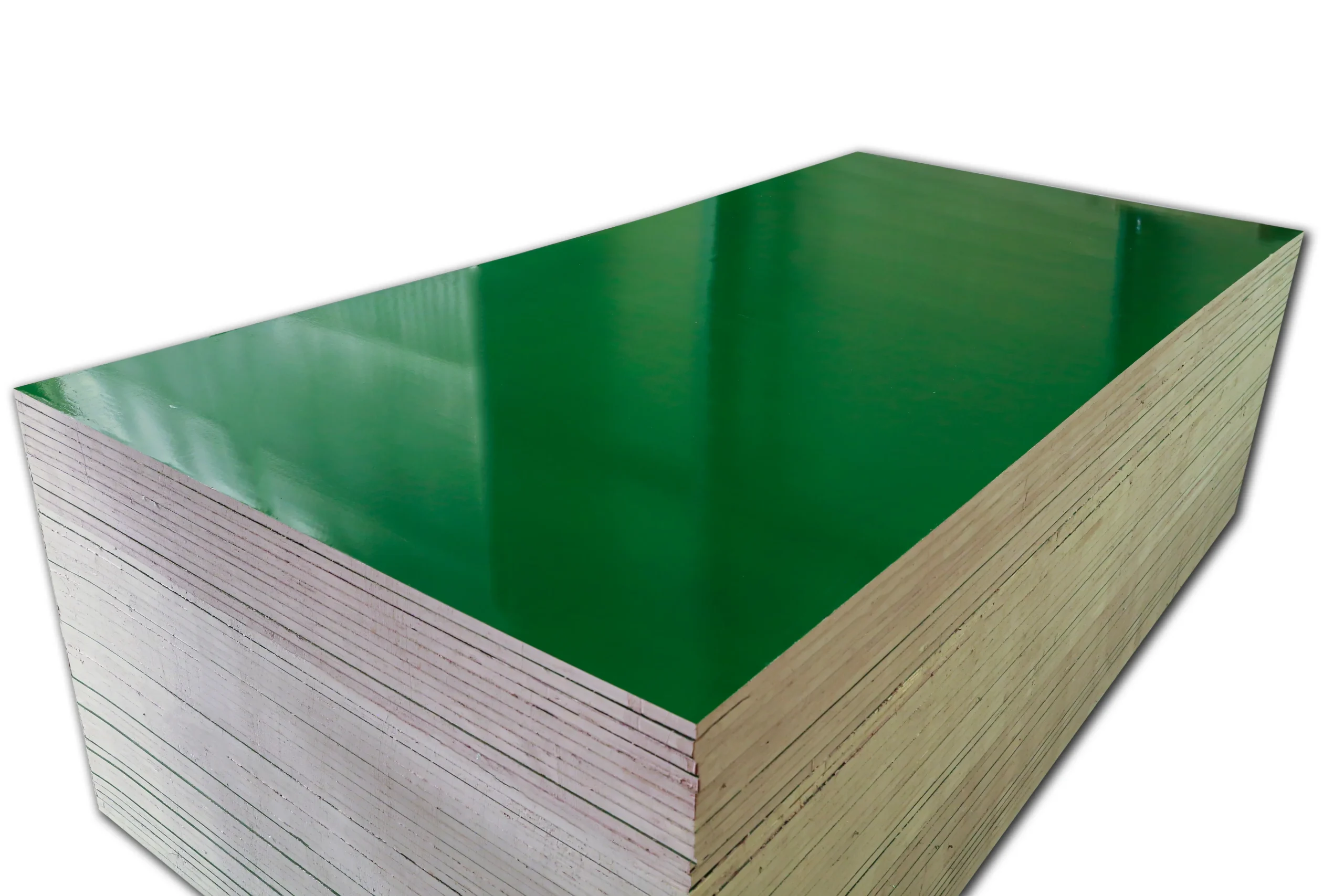

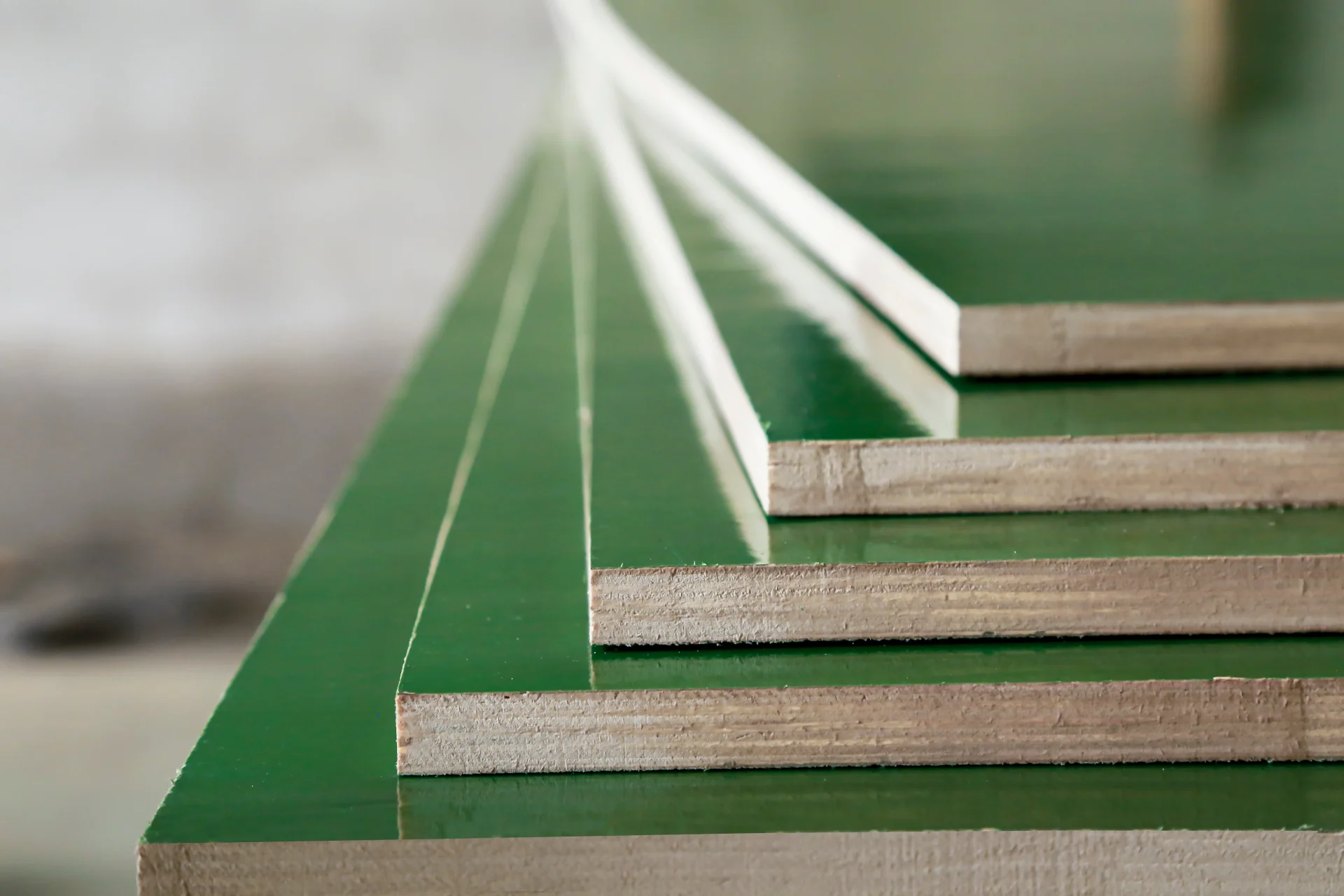

Durable Waterproof Plastic Film Faced Plywood is a new type of film-facing laminate. Its base material is particle board and medium fiber board, which are made by bonding the base material and the surface. The surface veneers are mainly domestic and imported, because they are fireproof, abrasion-resistant, and waterproof. In the production of all poplar plywood, each sheet is selected and repaired and used after secondary molding.

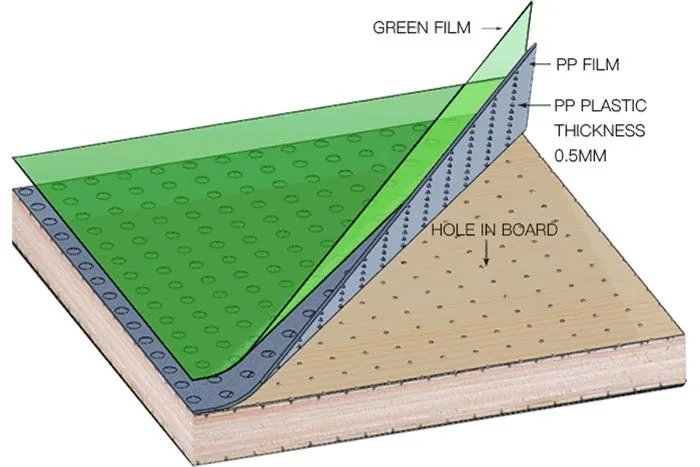

Compared with traditional laminated paper plywood, Durable Water Proof Plastic Film Faced Plywood uses pp plastic wear-resistant film on high-quality veneer.

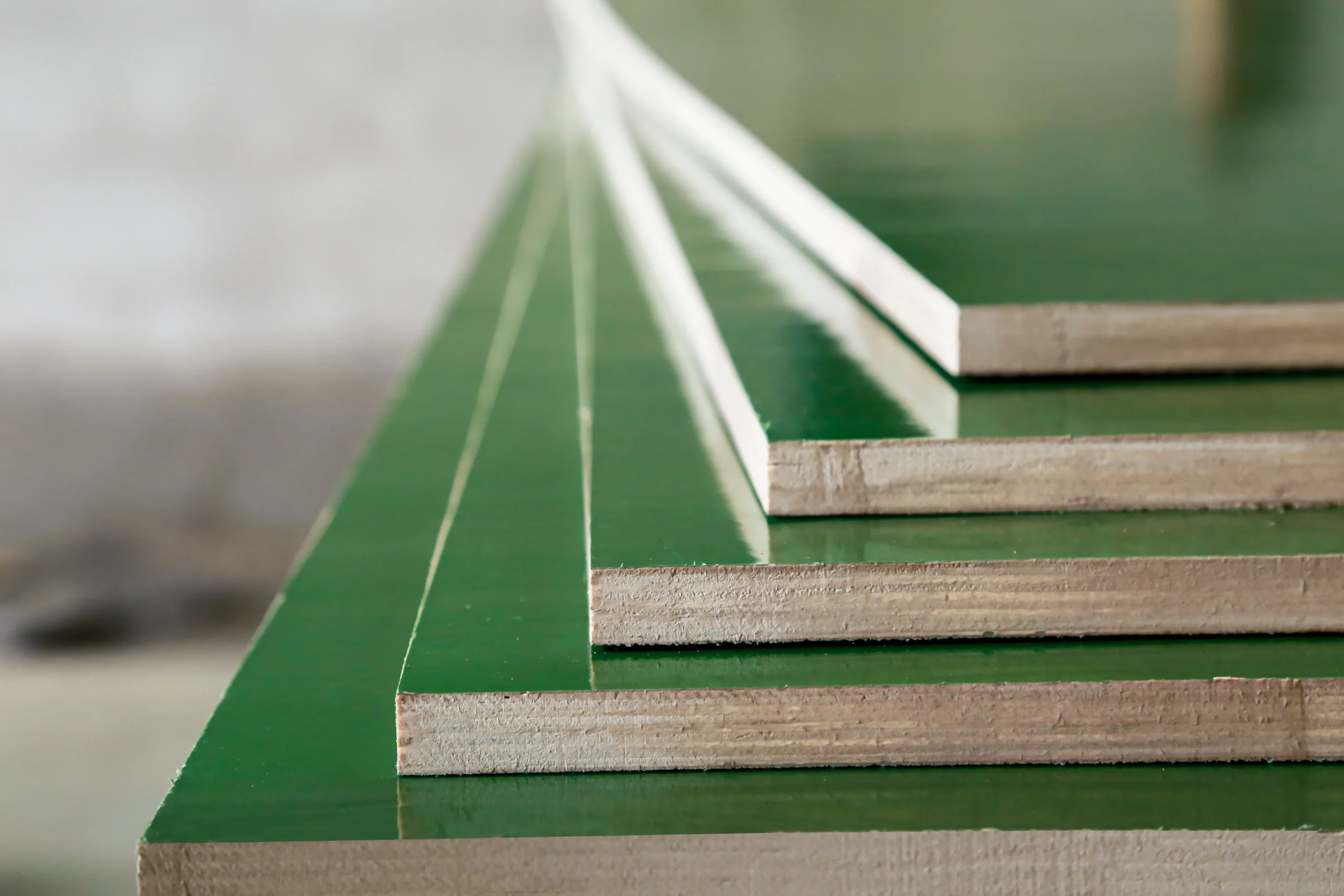

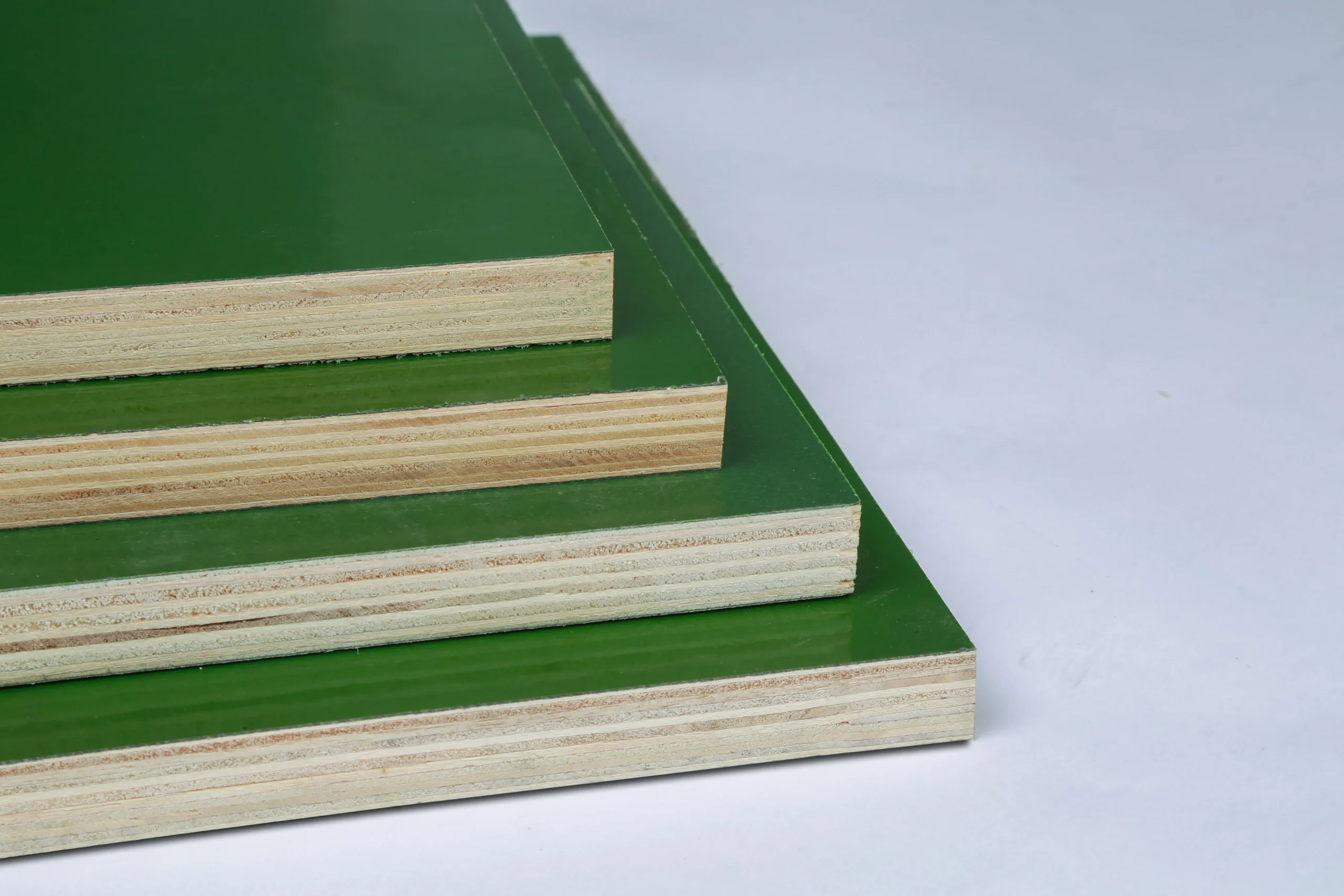

Compared with traditional laminated paper plywood, Durable Water Proof Plastic Film Faced Plywood uses pp plastic wear-resistant film on high-quality veneer. It is easy to demould, does not contain a release agent, does not stick to cement, and the concrete surface is very smooth. It has more reuse times than ordinary laminated plywood. It has perfect waterproof performance and wear resistance. Glue makes it stronger and increases the reuse time to 20-30 times. Durable Water Proof Plastic Film Faced Plywood is easy to transfer to the concrete build. It is waterproof, wear-resistant, crack-resistant and environmentally friendly. It is sealed with waterproof paint, and the color can be customized. It is used in real estate construction and formwork panels. It has stronger impact strength and high processability.

The advantages of durable waterproof plastic film-faced plywood are also obvious, such as good bonding strength, no glue, no break, waterproof, anti-corrosion, etc. When in use, the surface should be relatively smooth, with good flatness, and no carbonization, and the overall thickness of the board should be relatively uniform. Since waterproof glue and phenolic glue are used for bonding in production, the bonding strength is very high and can be greatly adapted to different usage scenarios.

PP Plastic Film Faced Plywood is a new type of film faced laminate. Compared with traditional film faced laminates, it has the following advantages:

- Easy to demould, release agent free, nonstick cement, concrete surface is very smooth.

- More reuse times than normal film faced plywood.

- Waterproof performance is perfect and wear resistant

详细信息

生产流程

原料储存

我们有多个仓库来储存所有原材料,如白杨木单板、硬木单板、无患子/Bintangor/Okoume/铅笔杉/松木面/背等。一旦新的原材料运送到我们的仓库,我们的工人就会对所有原材料进行检查,并将不同等级的木材放入不同的仓库。

原材料预处理

生产开始后,我们的工人会对原材料进行预处理,包括边接、胶合。

贴面组装

我们的工人会在流水线上一层一层地组装木皮。比如 18MM 就由 11 层木皮组成。

原板印前

单板组装过程结束后,所有原板都需要用冷压机进行预压。这样,原板就能被塑造成原胶合板。这个过程至少需要 2 个小时。

原木热压机

成型的原始胶合板将通过热压机进行层压。这个过程至少需要 1 个小时。热压后,生胶合板的粘合力会很强。

原木修补和抹灰

这个过程是为了填补未加工胶合板表面的缝隙。

原木打磨

将生胶合板放入砂光机。打磨后,生胶合板表面会变得光滑,厚度也会均匀。

面/背板组装

首先粘合原胶合板。然后,工人会在生胶合板的两面贴上面/背单板,如沙佩利/宾坦戈/奥古曼/铅笔杉。

冷压

面/背单板组装工序结束后,胶合板将再次放入冷压机中。这样面/背单板就能与生胶合板初步粘合。这个过程至少需要 1 个小时。

层压黄杨木热压机

这个过程至少需要 30 分钟。第二次热压后,面/背单板将与原胶合板牢固粘合。

切割和抛光

所有胶合板都将切割成标准尺寸,如 1220X2440MM。然后对胶合板进行抛光,使其表面/背面光滑。

检查和包装

检查木板是否有缺陷(如裂缝、密度不均、表面瑕疵等)。根据质量标准对合格的木板进行分级。堆放和包装木板,以便储存或装运。