Contraplacado revestido com película

Descrição

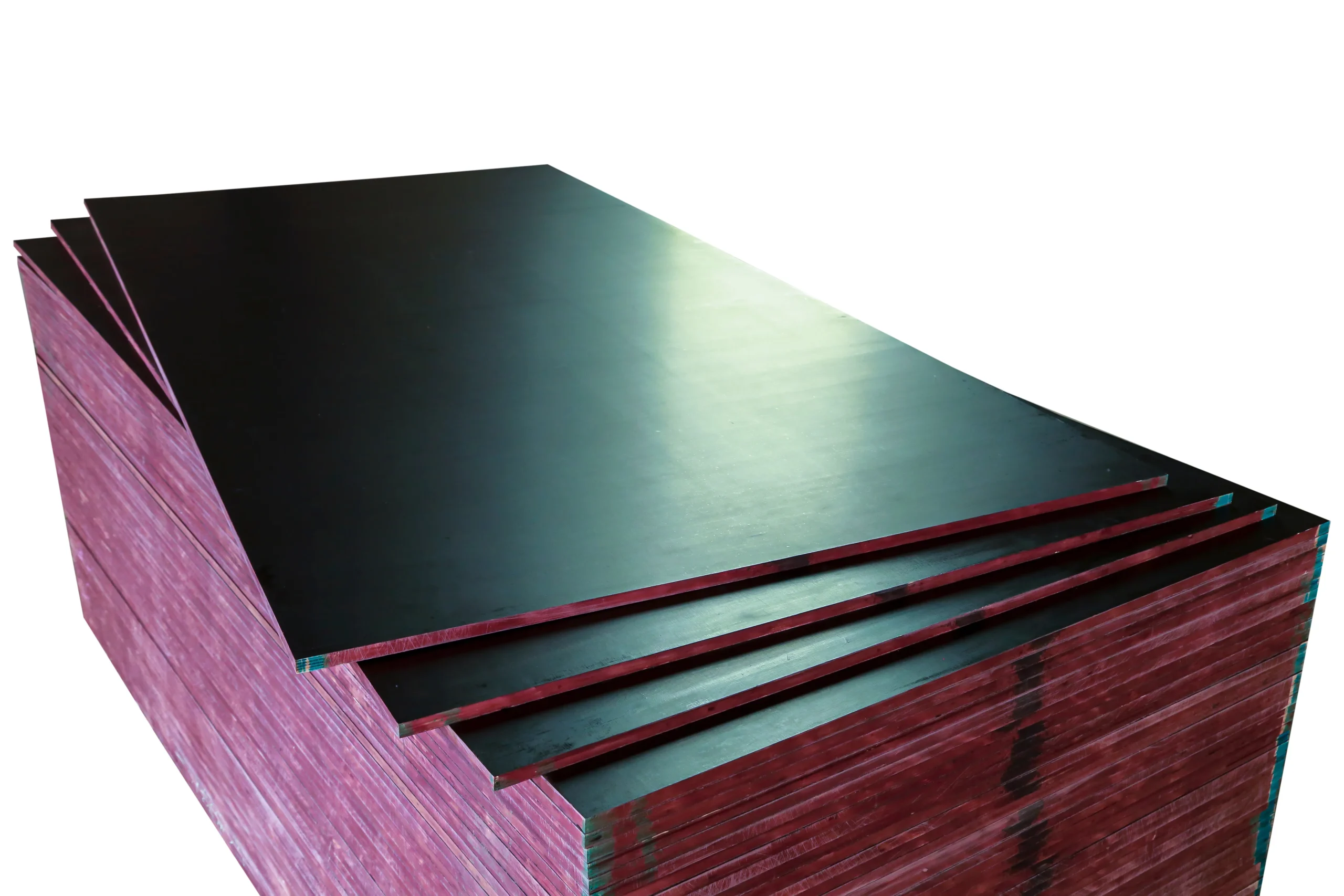

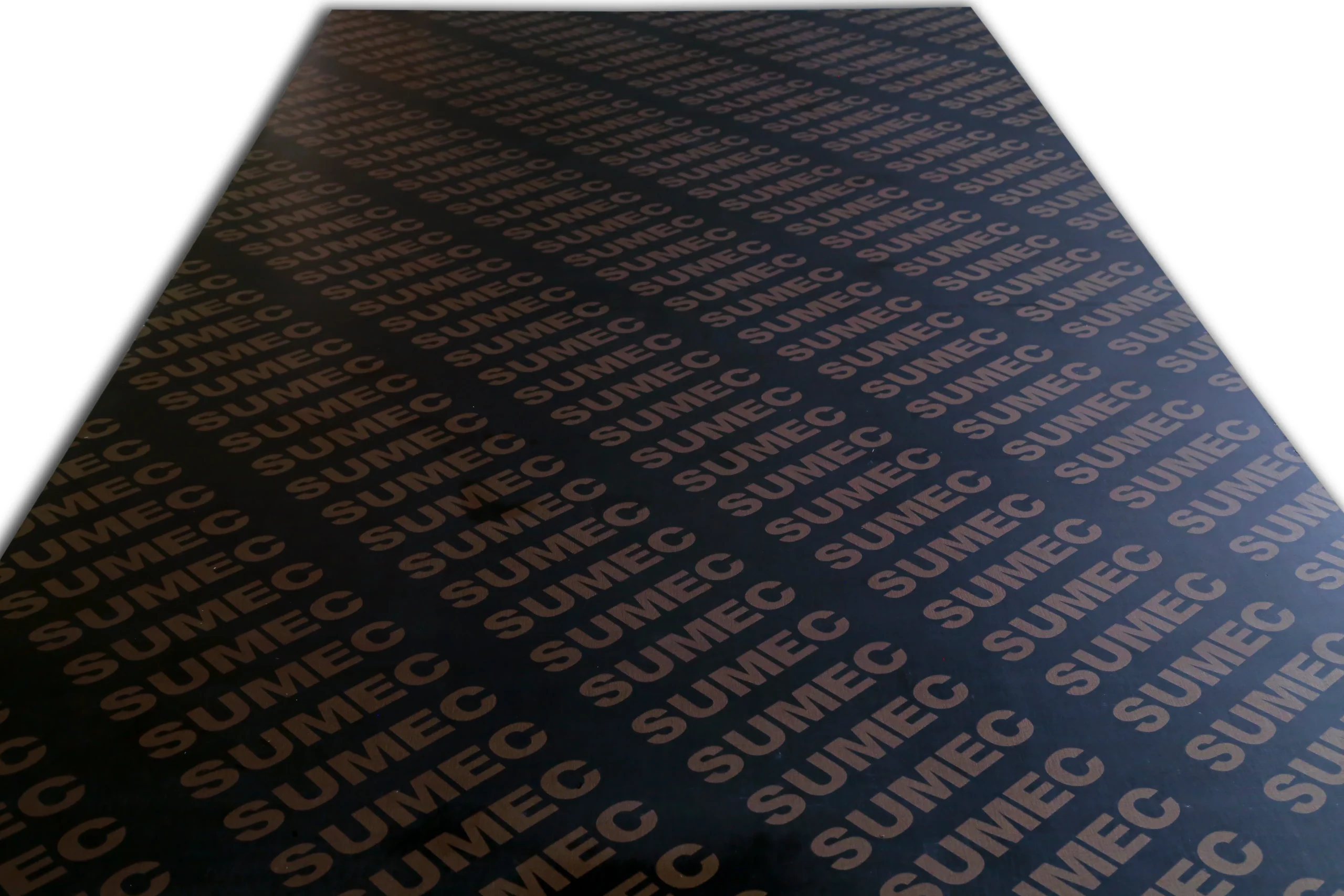

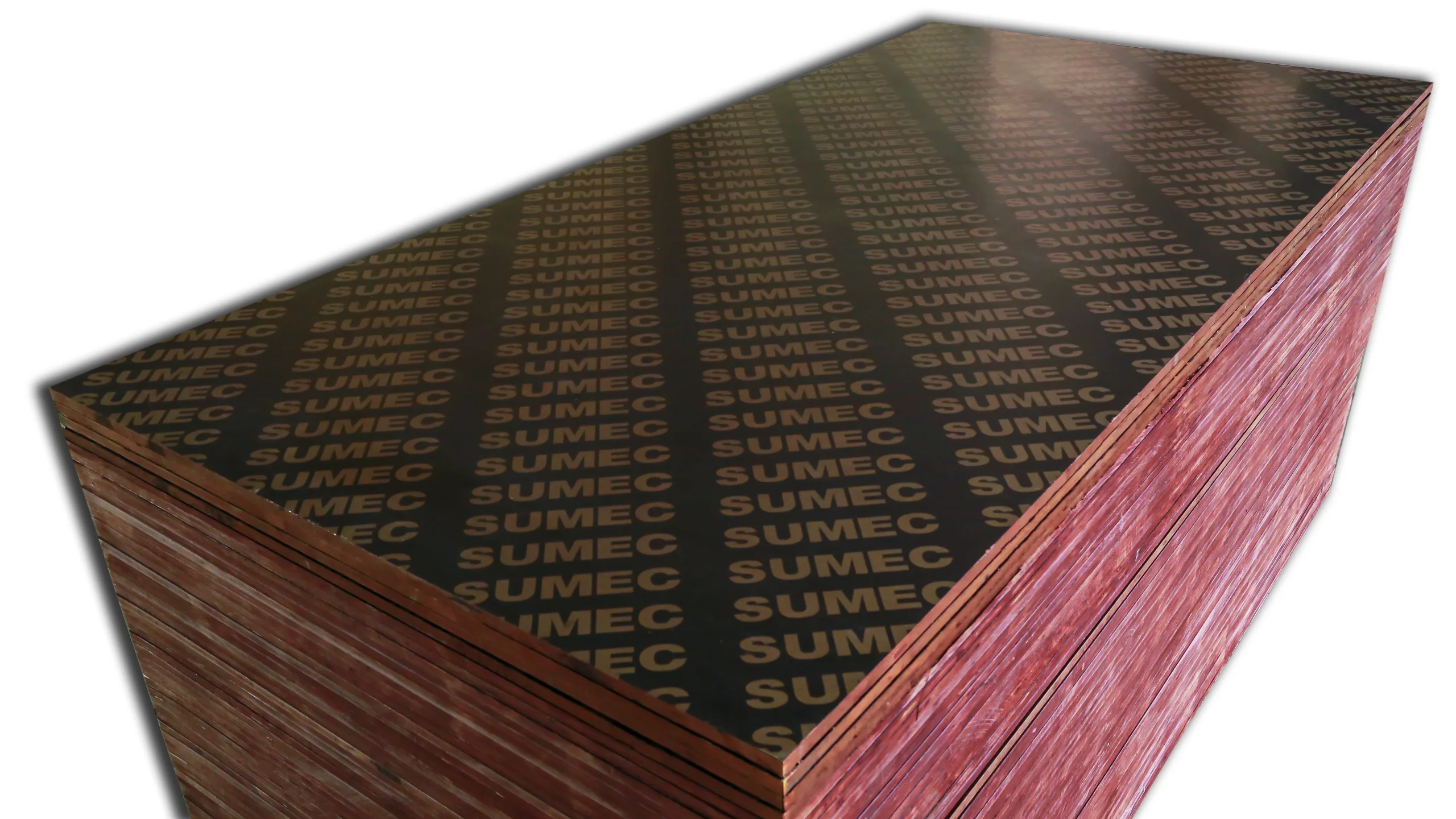

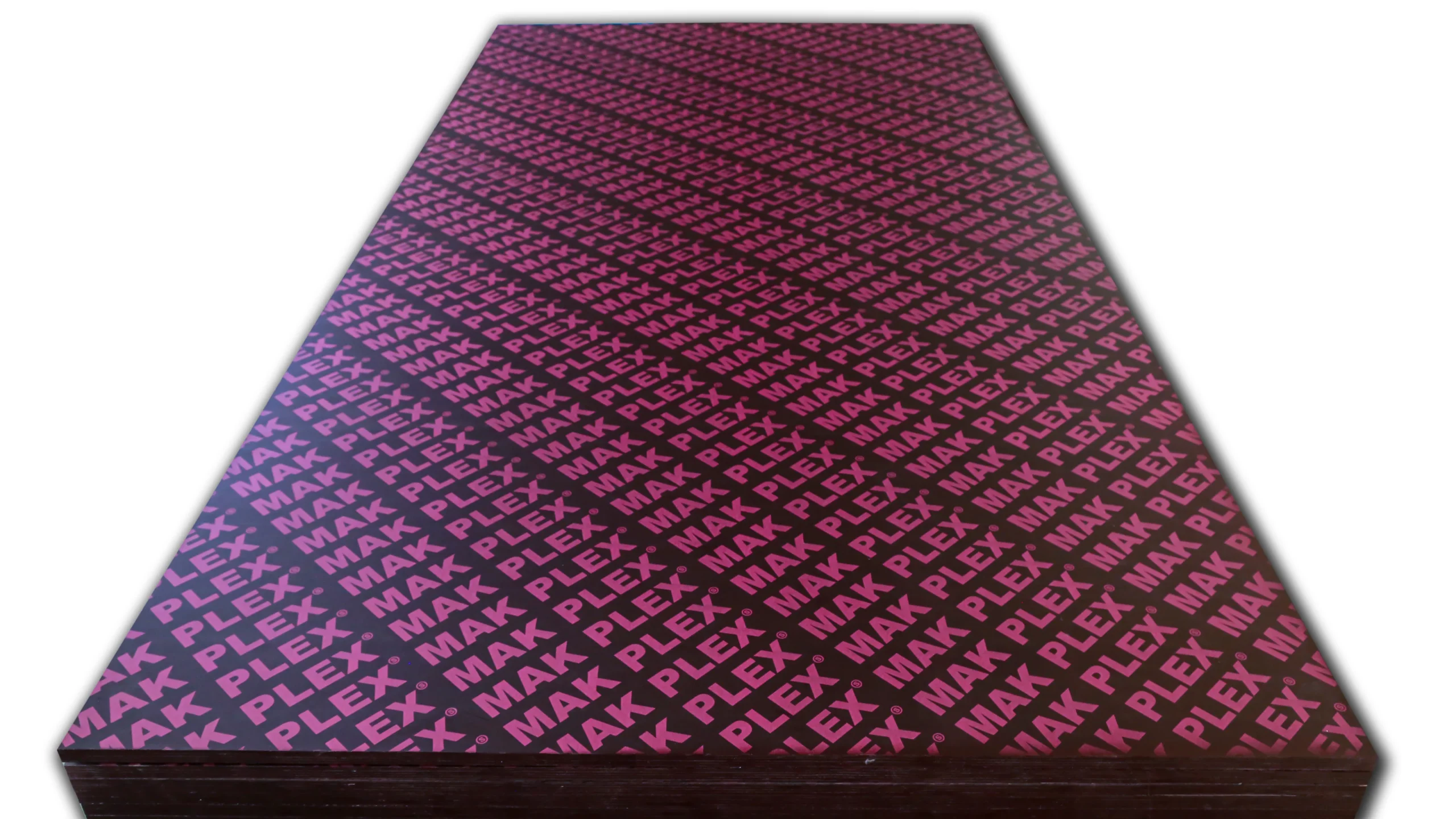

FILM FACED PLYWOOD is also called formwork plywood, shuttering plywoods, concrete form. Film faced plywood is the special plywood with two sides coated with wearable and water proof film. The film is adhesive impregnated paper, which are different from melamine paper overlay, PVC, MDO (MDO plywood) and HDO (HDO plywood). The function of the film is to protect the inside wood from moisture, water, weather and extend the plywood’s service life. Film faced plywood can be used in harsh and outside environment: shuttering plywood, formwork plywood, concrete formwork, floorboard, vehicle building.

Water Proof Film Faced Plywood is polished on both sides, so its surface is smooth, hard and durable. Plywood is characterized by excellent strength and rigidity, so it performs well in applications that require high strength and rigidity. Waterproof plywood also has good resistance to moisture, and is easy to machine and handle. By using different types of veneers, the surface characteristics of the plywood can be further enhanced.

Water Proof Film Faced Plywood has high weight-to-strength ratio and high durability. Moreover, it is easy to machine, easy to use standard mechanical trimming and standard method to fix. There are a wide range of film varieties and sizes to choose from. Better non-slip performance is suitable for floor applications. We can provide customized specifications and mechanical processing services, as well as high-quality technical services.

Detalhes

Processo de produção

ARMAZENAMENTO DE MATÉRIAS-PRIMAS

Dispomos de vários armazéns para armazenar todas as nossas matérias-primas, tais como folheado de choupo, folheado de madeira dura, Sapelli/Bintangor/Okoume/Pencil Cedar/Pine Face/Back, etc. Assim que as novas matérias-primas são entregues nos nossos armazéns, os nossos trabalhadores inspeccionam-nas e colocam as matérias-primas de diferentes graus em diferentes armazéns.

PRÉ-TRATAMENTO DE MATÉRIAS-PRIMAS

Uma vez iniciada a produção, os nossos trabalhadores procedem ao pré-tratamento das matérias-primas, incluindo a junção dos lados, a colagem.

MONTAGEM DE FOLHEADOS

Os nossos trabalhadores montam as lâminas de madeira uma camada por camada na linha de montagem. Por exemplo, o 18MM será composto por 11 camadas de lâminas de madeira.

PLACAS EM BRUTO PRÉ-IMPRESSÃO

Após o processo de montagem do folheado, todas as placas em bruto precisam de ser pré-pressionadas por uma máquina de prensagem a frio. Para que as placas em bruto possam ser moldadas em contraplacado em bruto. Este processo necessita de pelo menos 2 horas.

PRENSA A QUENTE DE MADEIRA DE PINHO EM BRUTO

O contraplacado em bruto moldado será laminado por uma máquina de prensagem a quente. Este processo necessita de pelo menos 1 hora. Após a prensagem a quente, a ligação do contraplacado em bruto será forte.

REPINTURA E BETUMAÇÃO DE MADEIRA EM BRUTO

Este processo destina-se a preencher as lacunas na superfície do contraplacado em bruto.

LIXAGEM DE MADEIRA EM BRUTO

Colocar o contraplacado em bruto na máquina de lixar. Depois de lixar, a superfície do contraplacado em bruto fica lisa e a espessura também fica uniforme.

MONTAGEM DO FOLHEADO FACE/VERSO

O contraplacado em bruto é colado em primeiro lugar. Em seguida, os trabalhadores colocam o folheado de face/verso, como Sapelli /Bintangor/Okoume/Pencil Cedar, em ambos os lados do contraplacado em bruto.

IMPRENSA FRIA

Após o processo de montagem do folheado de face/verso, o contraplacado será novamente colocado na máquina de prensagem a frio. Para que o folheado de face/verso se una inicialmente ao contraplacado em bruto. Este processo necessita de pelo menos 1 hora.

PRENSA A QUENTE DE MADEIRA COMPENSADA LAMINADA

Este processo necessita de pelo menos 30 minutos. Após a segunda prensagem a quente, o folheado da face e do verso ligar-se-á fortemente ao contraplacado em bruto.

CORTE E POLIMENTO

Toda a madeira compensada será cortada em tamanho padrão como1220X2440MM. Em seguida, o contraplacado será polido para tornar a face/verso liso.

INSPECÇÃO E EMBALAGEM

Inspecionar as placas para detetar defeitos (por exemplo, fissuras, densidade irregular, imperfeições da superfície). Classificar as placas qualificadas com base em padrões de qualidade. Empilhar e embalar as placas para armazenamento ou expedição.

Controlo de qualidade e embalagem