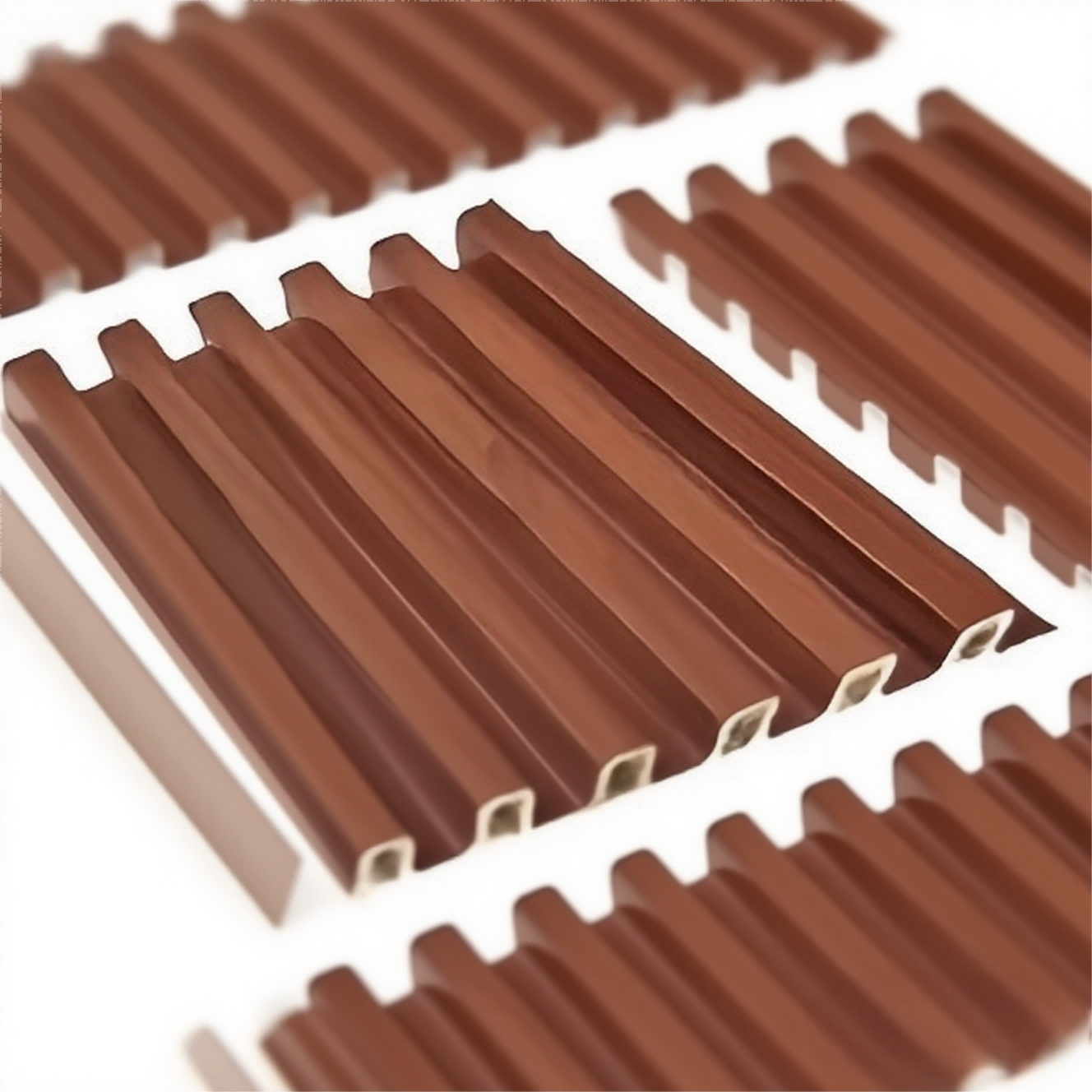

WPC Wall Panel

Description

WPC wall panel is made from two different materials: Wood Fiber and High Density Polyethylene, making the product durable, providing a good degree of weather and dirt resistance. WPC panels can be embossed or textured during producing to enhance their visual appeal and mimic natural materials like wood grain. This texture not only adds to the authenticity of the panels, but also provides a tactile experience which can enhance the overall ambiance of a space.

Detail

Production Process

RAW MATERIAL MIXING

Blend PVC resin, stabilizers, fillers, and additives in precise ratios using high-speed mixers to ensure uniformity.

HOT MELTING

Heat the mixed materials to 180-200°C in extruders, turning them into a homogeneous molten mass.

EXTRUSION MOLDING

Force the molten material through a die to form continuous panel blanks with fixed cross-sections.

SURFACE PRINTING/LAMINATION

Apply decorative patterns via roller printing or laminate with PVC films for aesthetics.

COOLING & SIZING

Cool the panels with water to stabilize dimensions, ensuring straightness and precise thickness.

CUTTING TO LENGTH

Cut the continuous panels into specified lengths (e.g., 2440mm) with precision saws.

PACKING

Wrap panels with PE film and pack on pallets to protect against scratches and moisture.

LOADING & SHIPPING

Load palletized products into containers, securing them for safe transportation.

Quality Control & Packing