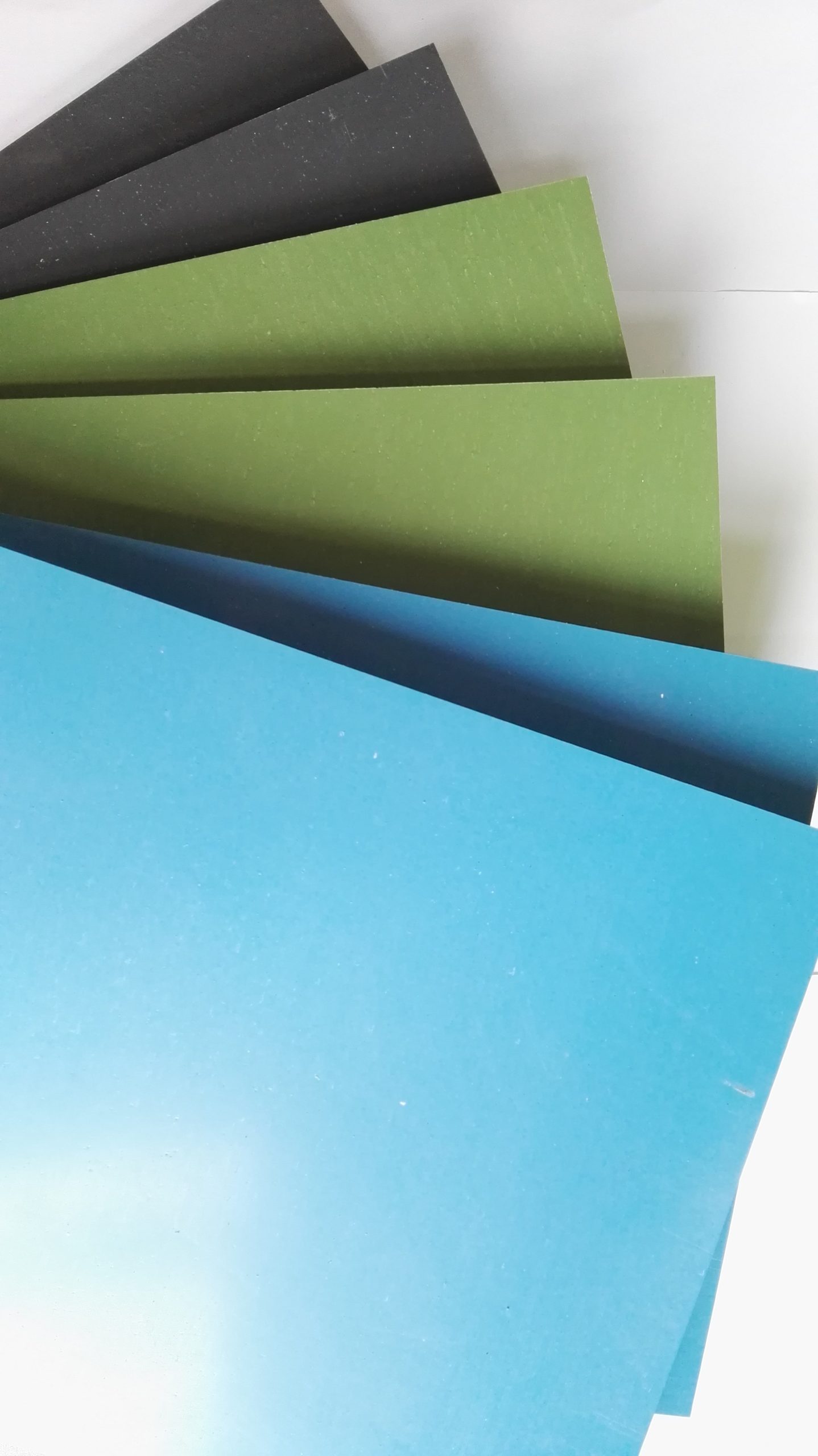

PVC Foam Board

Description

The PVC foam board is widely used for both indoor and outdoor applications. It comprises the chemical composition, Poly Vinyl Chloride, which is used in furniture, building, and advertising industries.

Made of lightweight and foamed PVC, this PVC foam board is moisture and corrosion-resistant. It is absolutely lightweight. It is also resistant to chemicals. The overall thickness of the material will range from 2 mm to 45mm. It is feasible to engrave, emboss, paint, print, laminate and mill the surface of the foam board according to your requirements. One of the most highlighting features of this foam board is that they will not decay with time and the color remains in the same new look for a long time without fading.

Detail

Production Process

RAW MATERIAL PREPARATION

– Collect raw materials such as wood logs, sawmill residues, and recycled wood.

– Remove impurities (e.g., metal, stones) and debark the logs.

– Cut the materials into small chips (2-5cm in length) using chippers.

FIBER PRODUCTIONG

– Steam the wood chips in a digester at 160-180°C for 20-30 minutes to soften the lignin.

– Grind the softened chips into fine fibers using a defibrator (mechanical or thermal-mechanical process).

FIBER DRYING

– Dry the fibers in a rotary dryer to reduce moisture content to 8-12%.

– Separate and screen the dried fibers to remove oversize particles.

GLUING AND ADDITIVE APPLICATION

– Mix the fibers with synthetic resin (mainly urea-formaldehyde resin) at a ratio of 8-12% of fiber weight.

– Add wax emulsion (for water resistance) and curing agents as needed.

– Ensure uniform distribution of adhesives through a blending system.

MAT FORMING

– Convey the fiber-resin mixture to a forming machine.

– Form a continuous, uniform loose mat with controlled thickness and density.

PRE-PRESSING

– Compress the loose mat in a pre-press machine to reduce volume and improve stability.

– Form a semi-hardened slab for easier handling in subsequent processes.

HOT PRESSING

– Transfer the pre-pressed slab to a multi-layer hot press.

– Apply high temperature (180-220°C) and pressure (2.5-4 MPa) for 3-10 minutes.

– The heat cures the resin, and pressure bonds the fibers into a solid board.

COOLING AND TRIMMING

– Cool the hot-pressed boards to room temperature using cooling racks or fans.

– Trim the edges to achieve standard dimensions (e.g., 2440×1220mm) with saws.

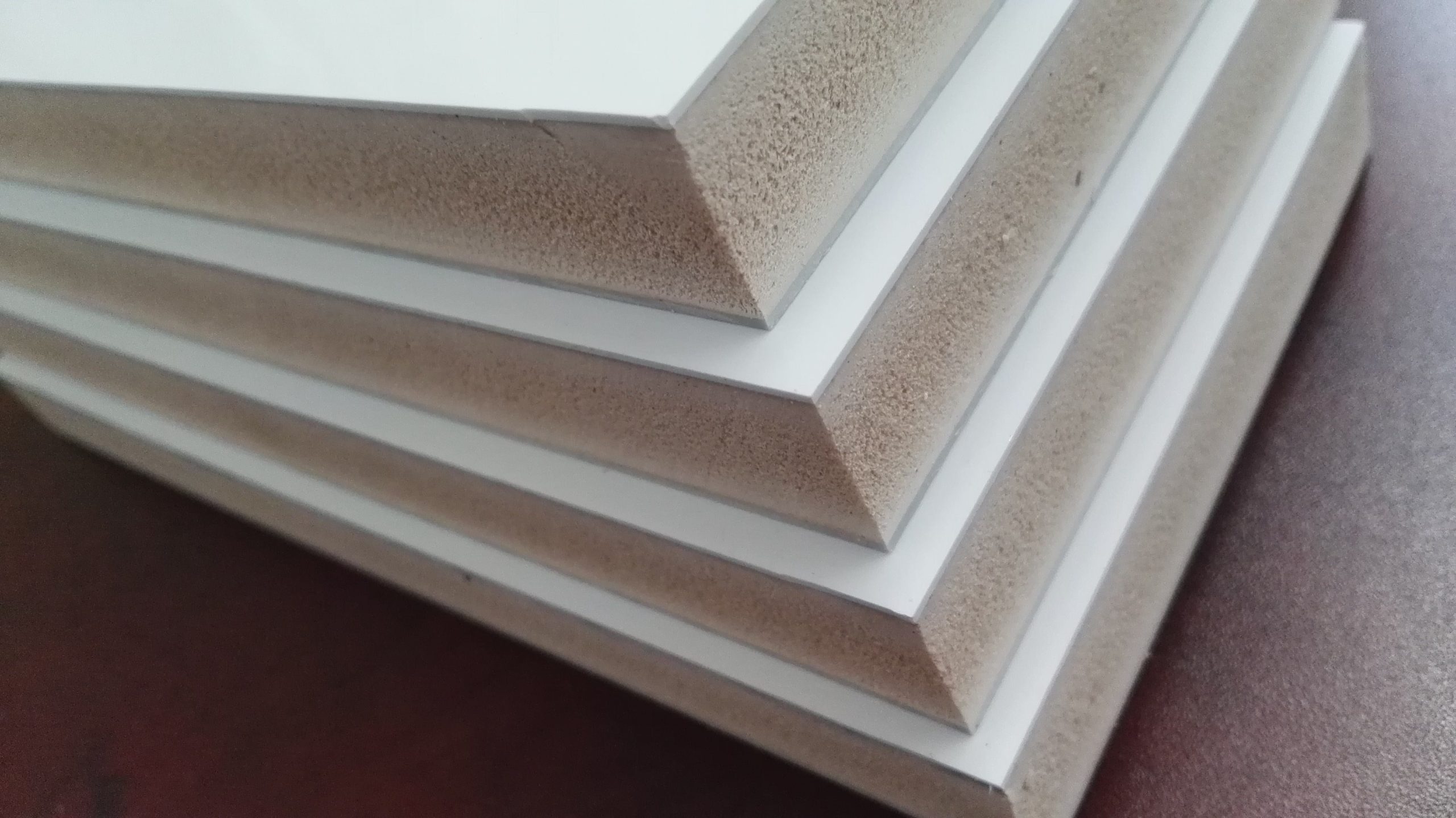

SANDING

– Sand both surfaces of the boards using multi-head sanding machines.

– Achieve smoothness and precise thickness (typically 3-30mm).

QUALITY INSPECTION AND PACKING

– Inspect boards for defects (e.g., cracks, uneven density, surface imperfections).

– Grade the qualified boards based on quality standards.

– Stack and package the boards for storage or shipment.

Quality Control & Packing