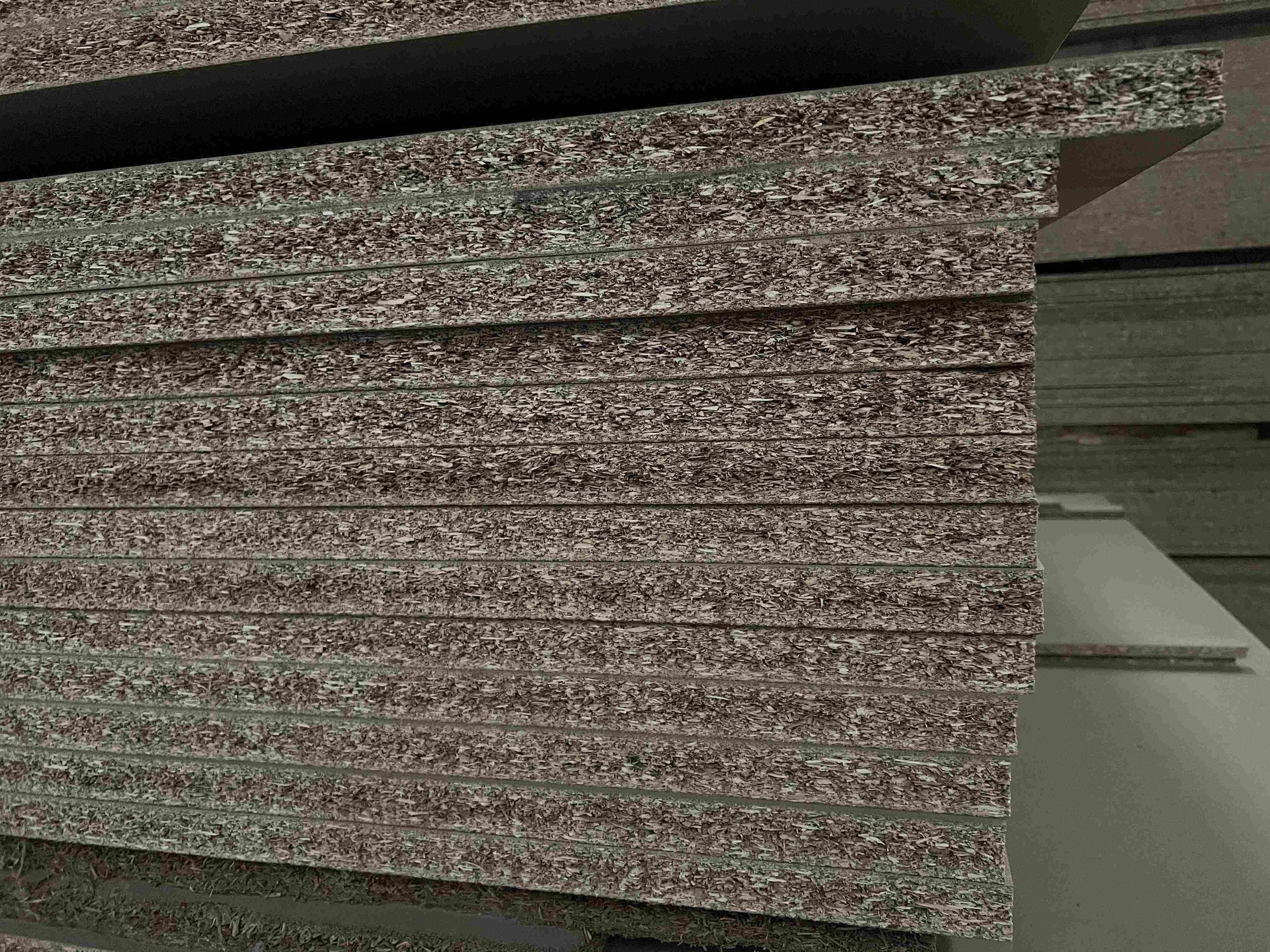

Panneau d'aggloméré

Description

Les panneaux de particules, parfois appelés panneaux de particules ou panneaux de fibres à faible densité, sont fabriqués en mélangeant de petites particules de bois à de la résine époxy, qui sont pressées ensemble sous une chaleur et une pression intenses pour produire un panneau rigide, généralement à la surface lisse. Les panneaux de particules sont disponibles dans une variété de densités pour répondre à différents besoins et utilisations, y compris des variétés à faible, moyenne et haute densité. Les panneaux de faible densité sont relativement souples et flexibles, tandis que les panneaux de haute densité sont plus rigides et peuvent être utilisés pour des applications plus lourdes.

Processus de production

PRÉPARATION DES MATIÈRES PREMIÈRES

- Collecter des matières premières telles que des grumes de bois, des résidus de scierie et du bois recyclé.

- Éliminer les impuretés (métal, pierres, etc.) et écorcer les grumes.

- Couper les matériaux en petits morceaux (2 à 5 cm de long) à l'aide d'une déchiqueteuse.

PRODUCTION DE FIBRESG

- Les copeaux de bois sont cuits à la vapeur dans un digesteur à 160-180°C pendant 20-30 minutes pour ramollir la lignine.

- Broyer les copeaux ramollis en fibres fines à l'aide d'un défibrateur (procédé mécanique ou thermomécanique).

SÉCHAGE DES FIBRES

- Sécher les fibres dans un séchoir rotatif pour réduire le taux d'humidité à 8-12%.

- Séparer et cribler les fibres séchées pour éliminer les particules trop grosses.

COLLAGE ET APPLICATION D'ADDITIFS

- Mélanger les fibres avec de la résine synthétique (principalement de la résine urée-formaldéhyde) dans un rapport de 8-12% du poids de la fibre.

- Ajouter une émulsion de cire (pour la résistance à l'eau) et des agents de durcissement si nécessaire.

- Assurer une distribution uniforme des adhésifs grâce à un système de mélange.

FORMATION DE LA NATTE

- Transporter le mélange fibre-résine vers une machine de formage.

- Former un tapis continu et uniforme, d'une épaisseur et d'une densité contrôlées.

PRÉPRESSION

- Comprimer le matelas en vrac dans une machine de prépresse afin de réduire le volume et d'améliorer la stabilité.

- Former une plaque semi-durcie pour faciliter la manipulation dans les processus ultérieurs.

PRESSAGE À CHAUD

- Transférer la dalle pré-comprimée dans une presse à chaud multicouche.

- Appliquer une température élevée (180-220°C) et une pression (2,5-4 MPa) pendant 3-10 minutes.

- La chaleur durcit la résine et la pression lie les fibres en un panneau solide.

LE REFROIDISSEMENT ET LE PARAGE

- Refroidir les planches pressées à chaud à température ambiante à l'aide de grilles de refroidissement ou de ventilateurs.

- Découper les bords pour obtenir des dimensions standard (par exemple, 2440×1220 mm) à l'aide de scies.

SANDING

- Poncer les deux surfaces des planches à l'aide de ponceuses multi-têtes.

- Obtenir un aspect lisse et une épaisseur précise (généralement de 3 à 30 mm).

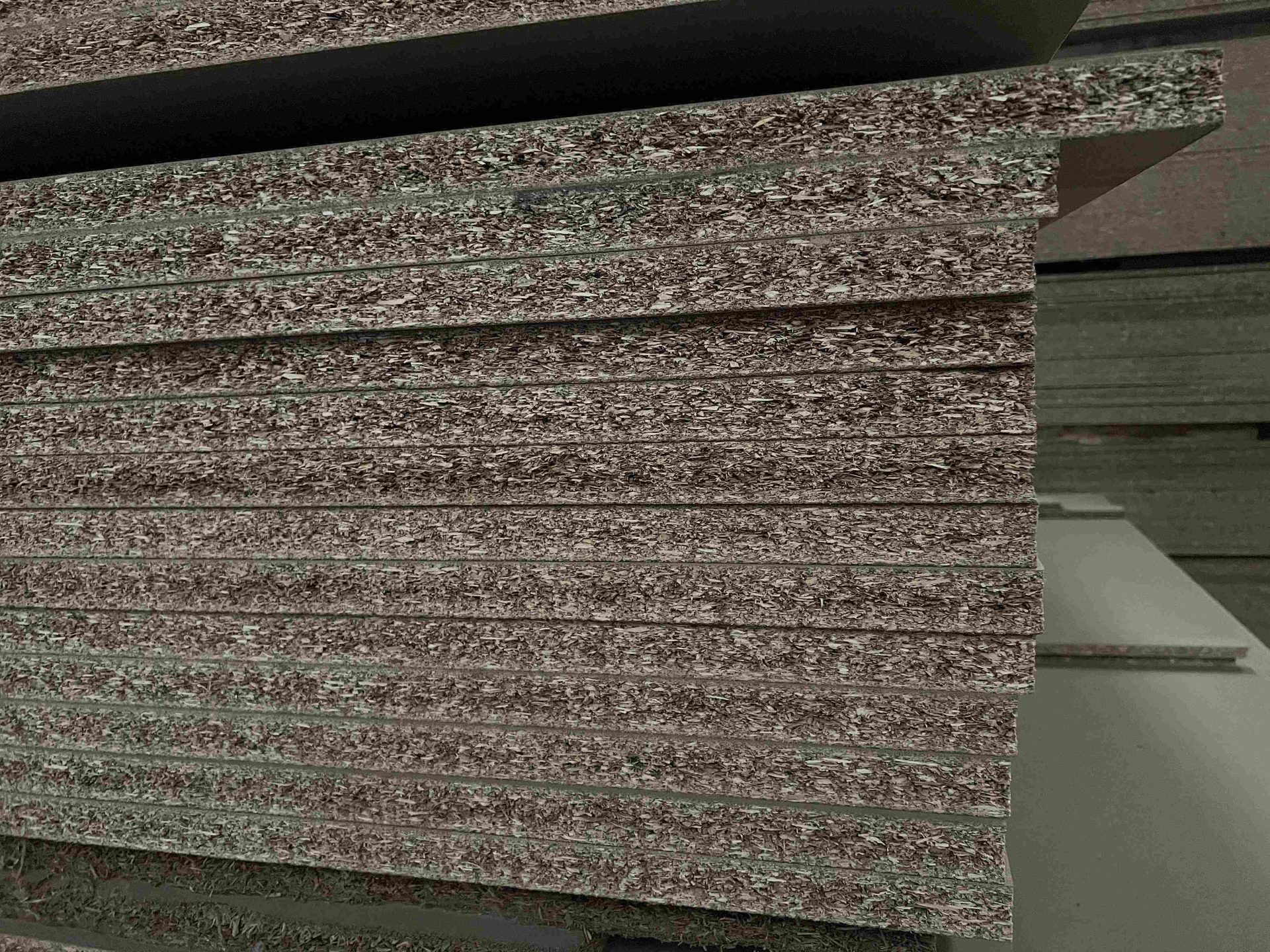

L'INSPECTION DE LA QUALITÉ ET L'EMBALLAGE

- Inspecter les planches pour détecter les défauts (par exemple, fissures, densité inégale, imperfections de surface).

- Classer les conseils d'administration qualifiés en fonction de normes de qualité.

- Empiler et emballer les panneaux pour le stockage ou l'expédition.

Contrôle de la qualité et emballage