说明

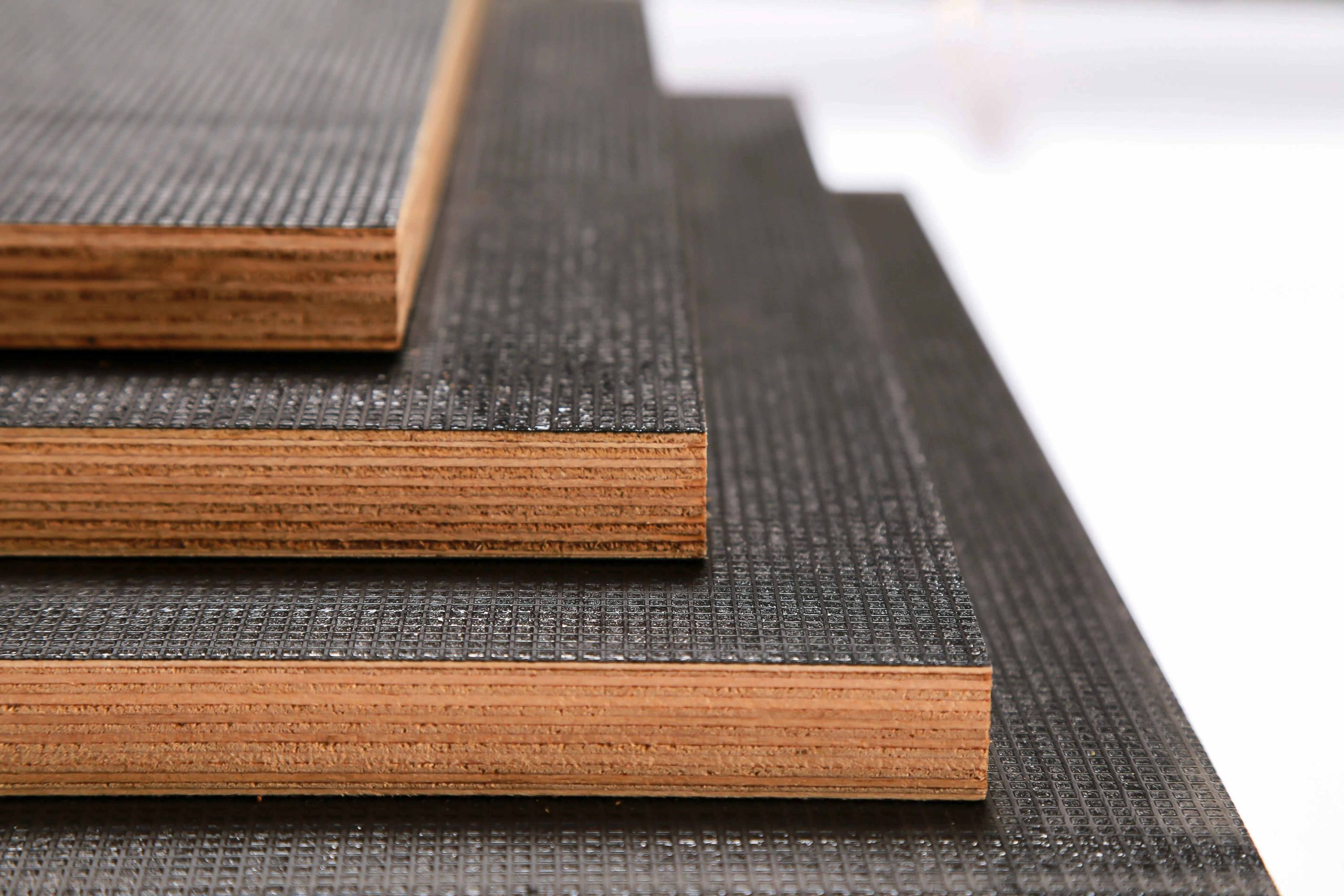

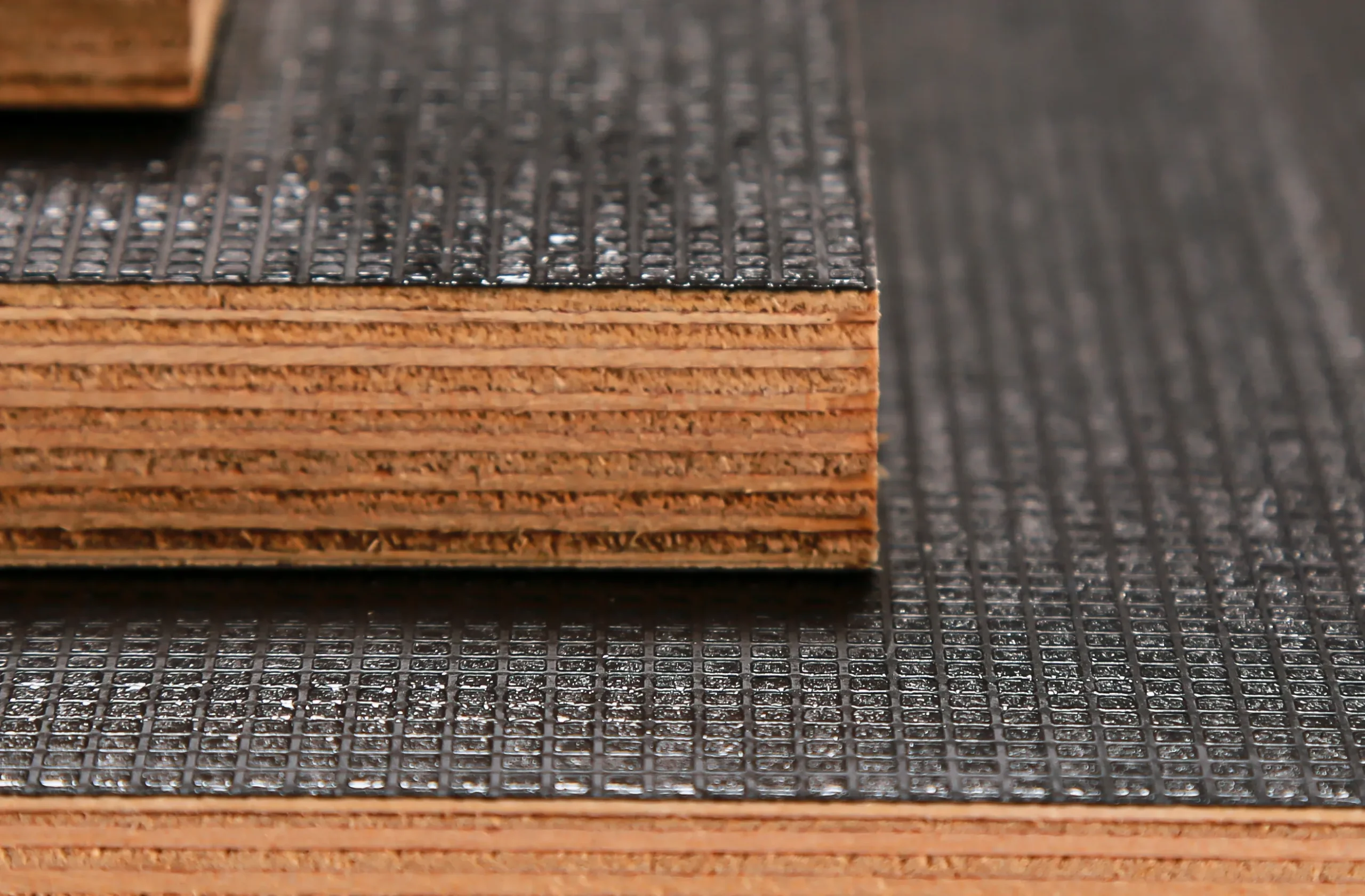

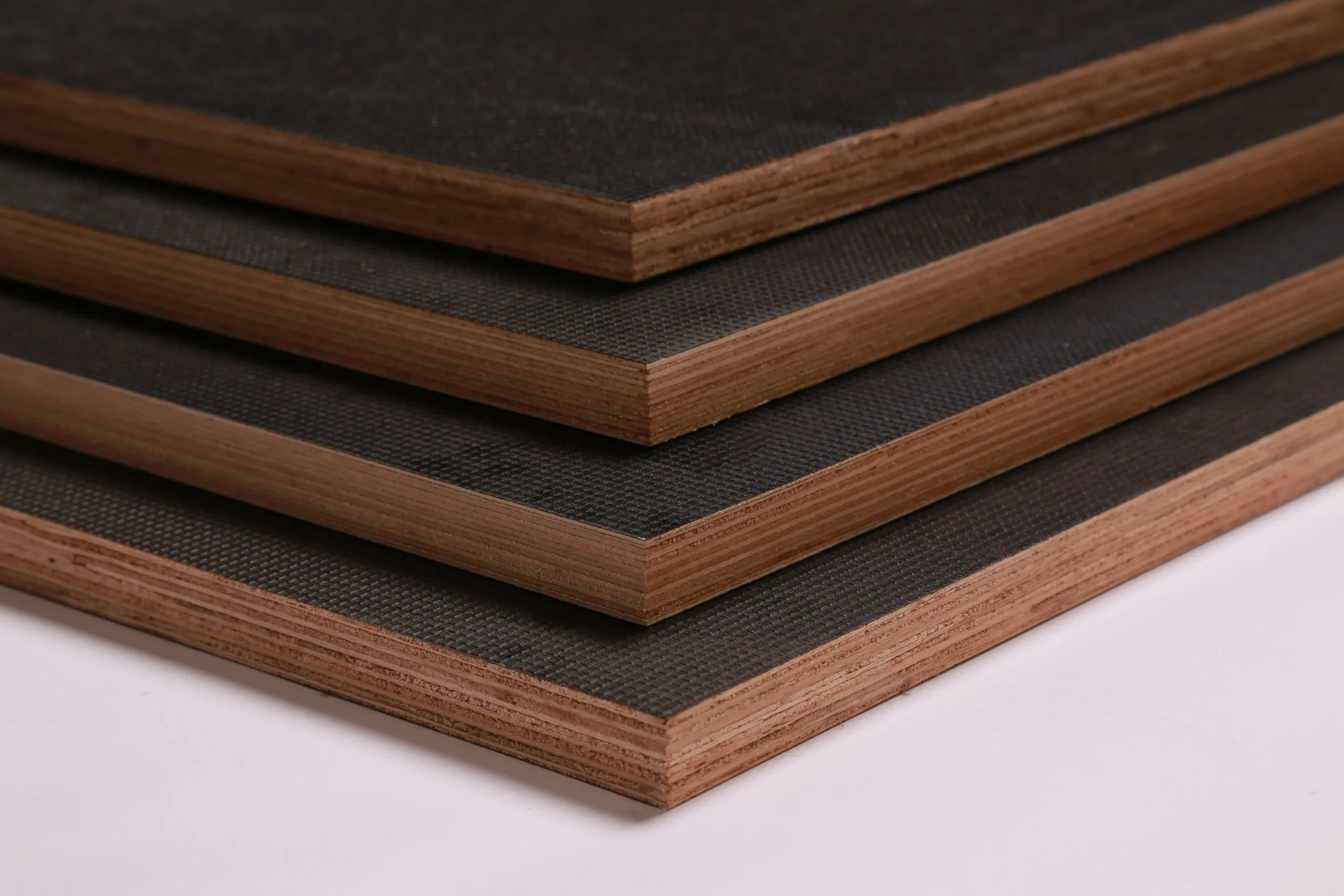

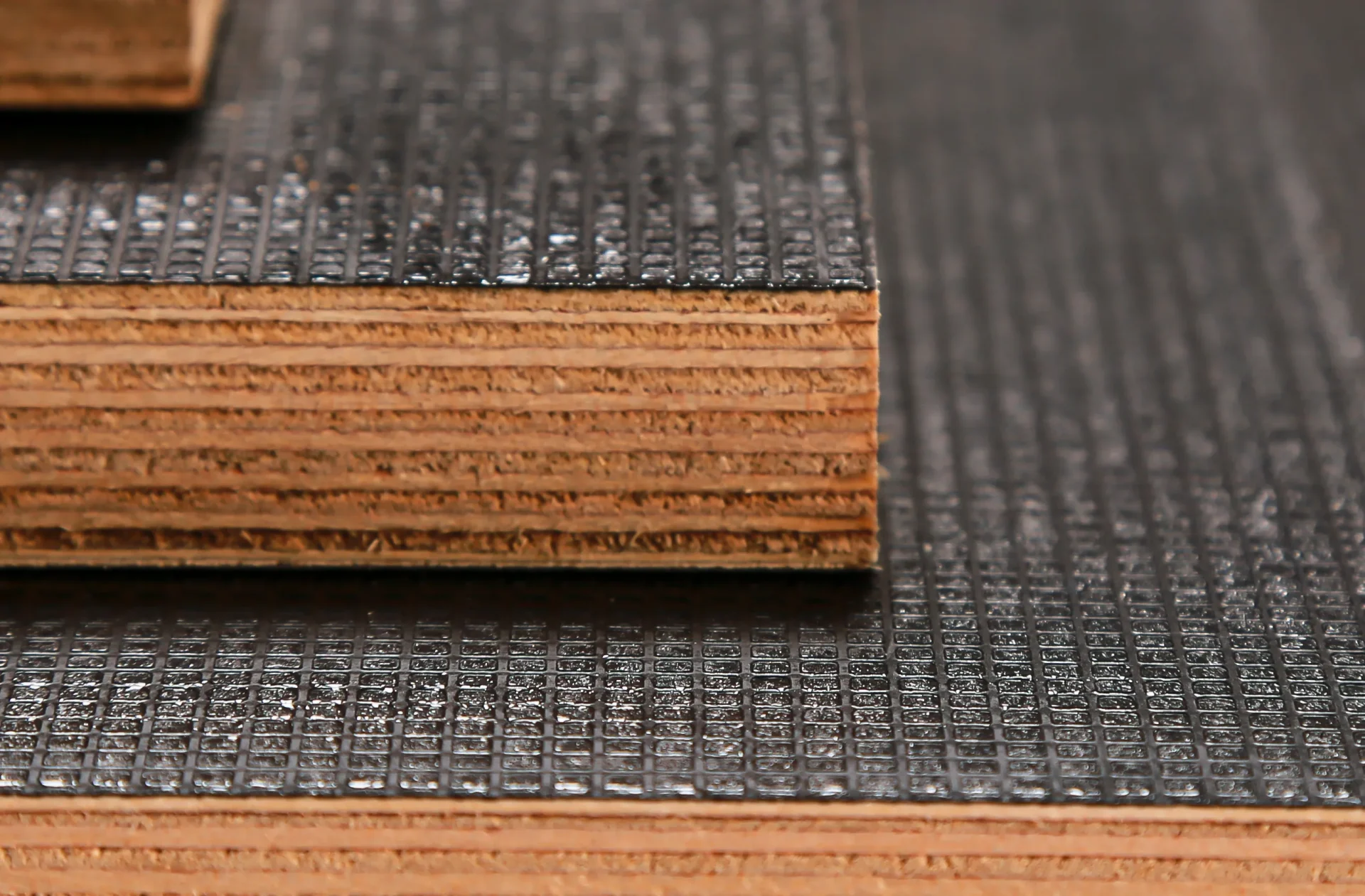

Water Proof Anti-slip Film Faced Plywood is made using hardwood and covered with a layer of waterproof phenolic film. The wear side has a rough antislip pattern and the reverse side is smooth film or raw plywood as needed. The edges of anti-slip plywood are sealed 3 times with waterproof paint. The wire mesh surface has high wear resistance and Anti-Slip properties. It is designed specially for internal & external applications such as farmwork, shop fitting, trailer bases, walkways and more. It offers an anti-slip mesh on one side & a smooth film face finish on the other side.

Anti-slip Film Faced Plywood is made in a similar fashion to regular smooth phenolic film faced panels with the additional process of applying a patterned, metallic press to the face to create the appropriate design. It’s a ideal products for the floors of commercial vehicles and walkways .

Water Proof Anti-slip Film Faced Plywood is manufactured with a quality Plywood core with a anti-slip mesh pattern on one side & a smooth film face finish on the under side. These boards are manufactured to high standards making them resistant to corrosion and moisture, making them the most durable choice especially for external application. We can also cut any piece of Plywood to your required size or pack together as many sheets as you require, delivery is offered or collections can be made from our depot for savings.

详细信息

生产流程

原料储存

我们有多个仓库来储存所有原材料,如白杨木单板、硬木单板、无患子/Bintangor/Okoume/铅笔杉/松木面/背等。一旦新的原材料运送到我们的仓库,我们的工人就会对所有原材料进行检查,并将不同等级的木材放入不同的仓库。

原材料预处理

生产开始后,我们的工人会对原材料进行预处理,包括边接、胶合。

贴面组装

我们的工人会在流水线上一层一层地组装木皮。比如 18MM 就由 11 层木皮组成。

原板印前

单板组装过程结束后,所有原板都需要用冷压机进行预压。这样,原板就能被塑造成原胶合板。这个过程至少需要 2 个小时。

原木热压机

成型的原始胶合板将通过热压机进行层压。这个过程至少需要 1 个小时。热压后,生胶合板的粘合力会很强。

原木修补和抹灰

这个过程是为了填补未加工胶合板表面的缝隙。

原木打磨

将生胶合板放入砂光机。打磨后,生胶合板表面会变得光滑,厚度也会均匀。

面/背板组装

首先粘合原胶合板。然后,工人会在生胶合板的两面贴上面/背单板,如沙佩利/宾坦戈/奥古曼/铅笔杉。

冷压

面/背单板组装工序结束后,胶合板将再次放入冷压机中。这样面/背单板就能与生胶合板初步粘合。这个过程至少需要 1 个小时。

层压黄杨木热压机

这个过程至少需要 30 分钟。第二次热压后,面/背单板将与原胶合板牢固粘合。

切割和抛光

所有胶合板都将切割成标准尺寸,如 1220X2440MM。然后对胶合板进行抛光,使其表面/背面光滑。

检查和包装

检查木板是否有缺陷(如裂缝、密度不均、表面瑕疵等)。根据质量标准对合格的木板进行分级。堆放和包装木板,以便储存或装运。