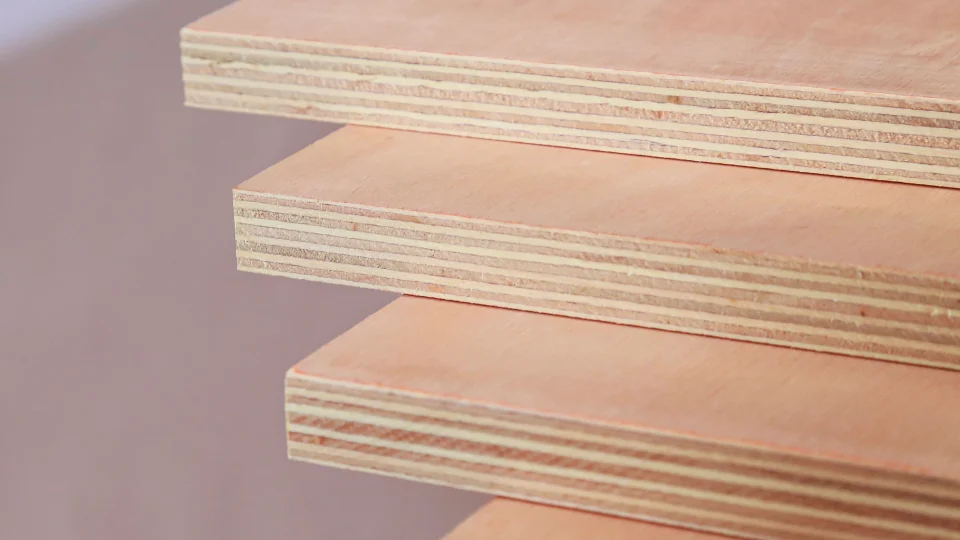

Contraplacado de okoume

Descrição

O contraplacado de Okoume é fabricado a partir da madeira da árvore Okoume. É por vezes chamada de mogno Okoume e tem um tom castanho-rosado ou vermelho pálido. O Okoume tem uma textura uniforme e o grão é reto a ligeiramente ondulado, com um aspeto entrelaçado e atraente. Deve ser selado para evitar a entrada de humidade, sendo pintado e acabado com epóxi e verniz para evitar quaisquer problemas de exposição aos elementos.

O contraplacado de okoume é normalmente utilizado na construção de barcos de corrida e noutras utilizações em que é necessária madeira leve. Também pode ser utilizado para a construção de mobiliário ou em armários de cozinha devido ao seu aspeto brilhante. O Okoume é durável, leve e atrativo, o que o torna adequado para o trabalho da madeira. Por exemplo, é possível revestir armários de cozinha com contraplacado de Okoume.

Detalhes

Processo de produção

ARMAZENAMENTO DE MATÉRIAS-PRIMAS

Dispomos de vários armazéns para armazenar todas as nossas matérias-primas, tais como folheado de choupo, folheado de madeira dura, Sapelli/Bintangor/Okoume/Pencil Cedar/Pine Face/Back, etc. Assim que as novas matérias-primas são entregues nos nossos armazéns, os nossos trabalhadores inspeccionam-nas e colocam as matérias-primas de diferentes graus em diferentes armazéns.

PRÉ-TRATAMENTO DE MATÉRIAS-PRIMAS

Uma vez iniciada a produção, os nossos trabalhadores procedem ao pré-tratamento das matérias-primas, incluindo a junção dos lados, a colagem.

MONTAGEM DE FOLHEADOS

Os nossos trabalhadores montam as lâminas de madeira uma camada por camada na linha de montagem. Por exemplo, o 18MM será composto por 11 camadas de lâminas de madeira.

PLACAS EM BRUTO PRÉ-IMPRESSÃO

Após o processo de montagem do folheado, todas as placas em bruto precisam de ser pré-pressionadas por uma máquina de prensagem a frio. Para que as placas em bruto possam ser moldadas em contraplacado em bruto. Este processo necessita de pelo menos 2 horas.

PRENSA A QUENTE DE MADEIRA DE PINHO EM BRUTO

O contraplacado em bruto moldado será laminado por uma máquina de prensagem a quente. Este processo necessita de pelo menos 1 hora. Após a prensagem a quente, a ligação do contraplacado em bruto será forte.

REPINTURA E BETUMAÇÃO DE MADEIRA EM BRUTO

Este processo destina-se a preencher as lacunas na superfície do contraplacado em bruto.

LIXAGEM DE MADEIRA EM BRUTO

Colocar o contraplacado em bruto na máquina de lixar. Depois de lixar, a superfície do contraplacado em bruto fica lisa e a espessura também fica uniforme.

MONTAGEM DO FOLHEADO FACE/VERSO

O contraplacado em bruto é colado em primeiro lugar. Em seguida, os trabalhadores colocam o folheado de face/verso, como Sapelli /Bintangor/Okoume/Pencil Cedar, em ambos os lados do contraplacado em bruto.

IMPRENSA FRIA

Após o processo de montagem do folheado de face/verso, o contraplacado será novamente colocado na máquina de prensagem a frio. Para que o folheado de face/verso se una inicialmente ao contraplacado em bruto. Este processo necessita de pelo menos 1 hora.

PRENSA A QUENTE DE MADEIRA COMPENSADA LAMINADA

Este processo necessita de pelo menos 30 minutos. Após a segunda prensagem a quente, o folheado da face e do verso ligar-se-á fortemente ao contraplacado em bruto.

CORTE E POLIMENTO

Toda a madeira compensada será cortada em tamanho padrão como1220X2440MM. Em seguida, o contraplacado será polido para tornar a face/verso liso.

INSPECÇÃO E EMBALAGEM

Inspecionar as placas para detetar defeitos (por exemplo, fissuras, densidade irregular, imperfeições da superfície). Classificar as placas qualificadas com base em padrões de qualidade. Empilhar e embalar as placas para armazenamento ou expedição.

Controlo de qualidade e embalagem