Best Plywood for Cabinets :Grade, Face & Core Selection

Choosing the right plywood is one of the most important decisions in cabinet construction. Cabinet-grade plywood impacts strength, stability, appearance, and long-term durability. Plywood performance varies by product. Its grade, face veneer, and core type directly determine its quality, consistency, and suitability for cabinet boxes, shelves, doors, and interior finishing.

This article clearly explains key plywood selection points: grade, face veneer, core material and thickness. Whether you’re renovating a kitchen or building custom furniture,this article will help you make smart choices.

What are Plywood Cabinets?

Plywood cabinets are storage units made from engineered plywood panels. These panels use 3–7 thin wood layers glued together. Each layer runs in a different grain direction. This build makes the cabinets strong, stable, and consistent.

Plywood resists warping, shrinking, and swelling better than solid wood. Common thickness is 1/2″ to 3/4″. It supports heavy daily use well. Plywood cabinets offer good durability, moisture resistance, and value. They work well for kitchens, bathrooms, and built-in storage.

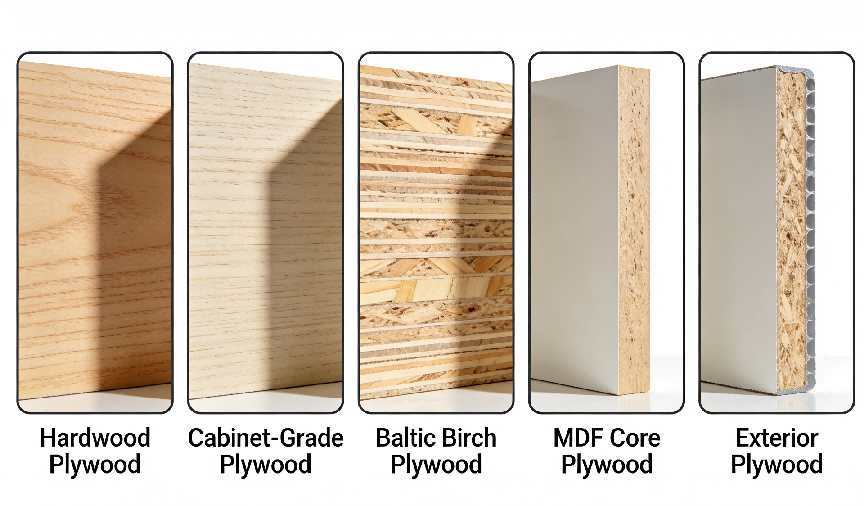

Key Plywood Types for Cabinets

Choosing the right plywood for cabinets makes a huge difference in how long they last, how they look, and their overall quality. Let’s check out the top plywood types that work best for building cabinets.

- Hardwood Plywood

Hardwood plywood is made from hardwoods like oak, birch, and maple. It’s relatively heavy, weighing 2.2 to 2.8 pounds per square foot, and it’s very strong—able to support up to 50 pounds per square foot. This makes it a great choice for furniture and cabinets that need to hold weight. Also, its smooth surface is easy to stain or paint, which gives cabinets a shiny, high-quality look.

- Cabinet-Grade Plywood

Cabinet-grade plywood,its face veneer is 1/28 to 1/32 inch thick, and its core is made of solid hardwood strips or good-quality softwood layers. It’s very durable, lasting more than 30 years indoors. That makes it a good choice for cabinet parts and high-end furniture.

- Baltic Birch Plywood

Baltic birch plywood has a uniform core material with a fine texture and extremely high strength, with a tensile strength of up to 1800 psi, making it suitable for high-intensity applications. It is a popular choice for high-end cabinetry and furniture projects.

- MDF Core Plywood

MDF Core Plywood has a smooth, flat core made of medium-density fiberboard with a density of 500-600 kg/m³. Its smooth surface absorbs paint well, preventing any wood grain from showing and ensuring a clean, even finish. Suitable for painted cabinets and door panels.

- Exterior Plywood

Exterior Plywood is bonded with waterproof adhesive. It is moisture-resistant and not easily damaged, making it ideal for outdoor cabinets and storage spaces in humid environments.

How to choose the best Plywood for Cabinets?

When customizing or purchasing cabinets, the choice of plywood is crucial in determining its durability, stability, and final appearance. To make an informed choice, you need to consider several key factors: veneer grade, quality, core material, and thickness.

1.Understanding Plywood Grades

The grading standards for plywood are set by the American Plywood Association (APA). Different grades will have different qualities, durability, and appearance.

Below are the four main grades of cabinet plywood to help you make an informed choice.

| Grade | Quality Level | Key Features | Common Uses |

| Grade A | Highest | Smoothwith minimal imperfections | High-end cabinetry FurnitureDecorative panels |

| Grade B | Good | Inorimperfections filled in | Cabinetsfurniture with slightly less visible surfaces |

| Grade C | Lower | Knots up to 1.5 inches widesmall knotholes visible repairs | Internal panelsStructural applications |

| Grade D | Lowest | Large knots (up to 2.5 inches wide)Unfixed flaws | Internal decorLow-cost construction |

Grade A plywood is the best for visible cabinet surfaces—its perfect finish means you don’t need to sand or fill it a lot. Grade D is only for parts that don’t need to look good, like cabinet back panels or internal braces. For most homeowners, Grade B/C works well for semi-visible parts like cabinet sides—it balances cost and looks.

2.Face Veneer & Core Selection Tips

- Face Veneer Quality

The face veneer is the outermost layer of plywood, and it affects both looks and durability. Choose thick face veneers to hide flaws in the core and make staining or painting easy.

Common veneer cutting methods include:

- Rotary cut: Broad, swirling grain, suitable for modern designs.

- Flat cut: Straight, even grain, perfectly suited for traditional cabinetry.

These two cutting methods present different textures and can be chosen according to design style.

- Core Material Considerations

Plywood core materials vary in density, strength, and cost. Choosing the right core material requires considering factors such as load-bearing requirements, whether staining or painting is necessary, and budget. Each core material has its advantages and disadvantages:

- Solid wood core: Solid wood core is made of hardwood strips such as oak and maple glued together, resulting in extremely high strength. Although it is 15%-20% heavier than medium-density fiberboard (MDF) core, it has a longer lifespan and is more durable and has a stronger load-bearing capacity than particleboard core. It is an ideal choice for cabinet shelves and load-bearing side panels.

- MDF Core: MDF core has a density of 500-600 kg/m³. Its surface finish and moisture resistance are superior to particleboard core material, and it can be painted directly without pretreatment. It is 10%-15% cheaper than solid wood core material, making it particularly suitable for painted cabinets. However, its moisture resistance is poor, making it unsuitable for humid environments such as bathrooms. Learn more in our guide Plywood vs. OSB vs. MDF: Which Board Is Best for Your Project?

- Particleboard Core:Particleboard core is made of wood particles and resin bonded together. It is prone to swelling when exposed to water and requires edge sealing with boards or paint. Its price is 25%-30% lower than medium-density fiberboard (MDF) core material. However, its durability is poor, and its load-bearing capacity and lifespan are far lower than solid wood core material. It is suitable for lightweight cabinet back panels or drawer bottoms.

3.Choosing the Right Plywood Thickness

The thickness of plywood affects its strength: if it’s too thin, it tends to sag under load;if it’s too thick, it adds unnecessary weight and cost. Therefore, choosing the right plywood thickness depends on the specific type of application. Below is a detailed breakdown of common thicknesses for cabinet uses:

| Épaisseur (Imperial) | Épaisseur(mm) | Recommended Uses | Key Benefits |

| ¾″ | 18mm | Side panelsBottom panels shelving | Most durable |

| ½″ | 12mm | Upper cabinet sidesLightweight shelves | Saves money for non-heavy-duty parts; May require extra support |

| ¼″ | 6mm | Drawer bottoms,Cabinet backsDoor panels | Lightweight needs framing support |

Thus, for most furniture and cabinet projects, ¾″ plywood remains the best option as it offers the ideal balance of strength, versatility, and reliability.

Pro Selection Tips for Cabinet Plywood

Follow these steps for an easier plywood selection:

1.Decide if it’s for Indoor or Outdoor Use: If the project is outdoors, choose exterior plywood, as it’s water-resistant and durable.If it’s indoors, choose the appropriate panel type based on the specific scenario.

2.Understand the Plywood Grading System

Plywood comes in various grades, which impact its appearance and strength.

Cabinet-grade plywood is typically used for high-end cabinetry and furniture projects. Grades like A, B, and C indicate the quality of the plywood, with A being the highest quality, free of visible defects, and perfect for visible areas.

B-grade plywood may have a few minor imperfections. But still provides a solid base. When choosing plywood for cabinets, it’s important to match the grade to your intended use.

3.Choose the Thickness: Use ¾ ″for structural components and ¼″ for drawer bottoms or cabinet backs.

4.Inspect for Quality: Choose plywood with clean, gap-free edges. Edges of plywood 18 mm or thicker are easier to finish and more stable over long-term use. Run your finger along the edge; if you feel gaps or unevenness, it indicates poor quality.

Last tip: Always buy 10-15% extra plywood. This covers cutting waste and any small mistakes, so you won’t run out of material mid-project.

Frequently Asked Questions (FAQ)

Q1:Can I use ½″plywood for cabinet sides?

A1:While ½ ″is an option for smaller projects, ¾″ plywood is generally recommended for structural integrity.

Q2.Does plywood warp over time?

A2:High-quality cabinet-grade plywood is dimensionally stable and resists warping, making it a reliable choice for long-lasting furniture.

Q3.Need Help Selecting the Right Plywood?

A3:Suppliers like SUMEC Building Material Supply can give you personalized advice for your project—whether you need structural plywood or something with a special finish. They can also provide test reports to prove the plywood’s quality, which is key for commercial projects or if you need to make a warranty claim.

En savoir plus sur nos produits ?

Contact