3/4″ Plywood Guide: Thickness, Types & Applications

3/4″ plywood is a popular, strong material for building and DIY projects. It’s labelled 3/4″ but actually measures about 23/32 inches (19mm). Made of glued wood layers, it resists warping and holds heavy loads well. This guide breaks down what 3/4″ plywood is, its types, how it stacks up against thinner options, when to use it, and how to pick the right thickness. Whether you’re building a deck, cabinets, or shelves, this simple guide helps you use 3/4″ plywood correctly.

Image Source:699pic.com

Table of Contents

What Is 3/4” Plywood?

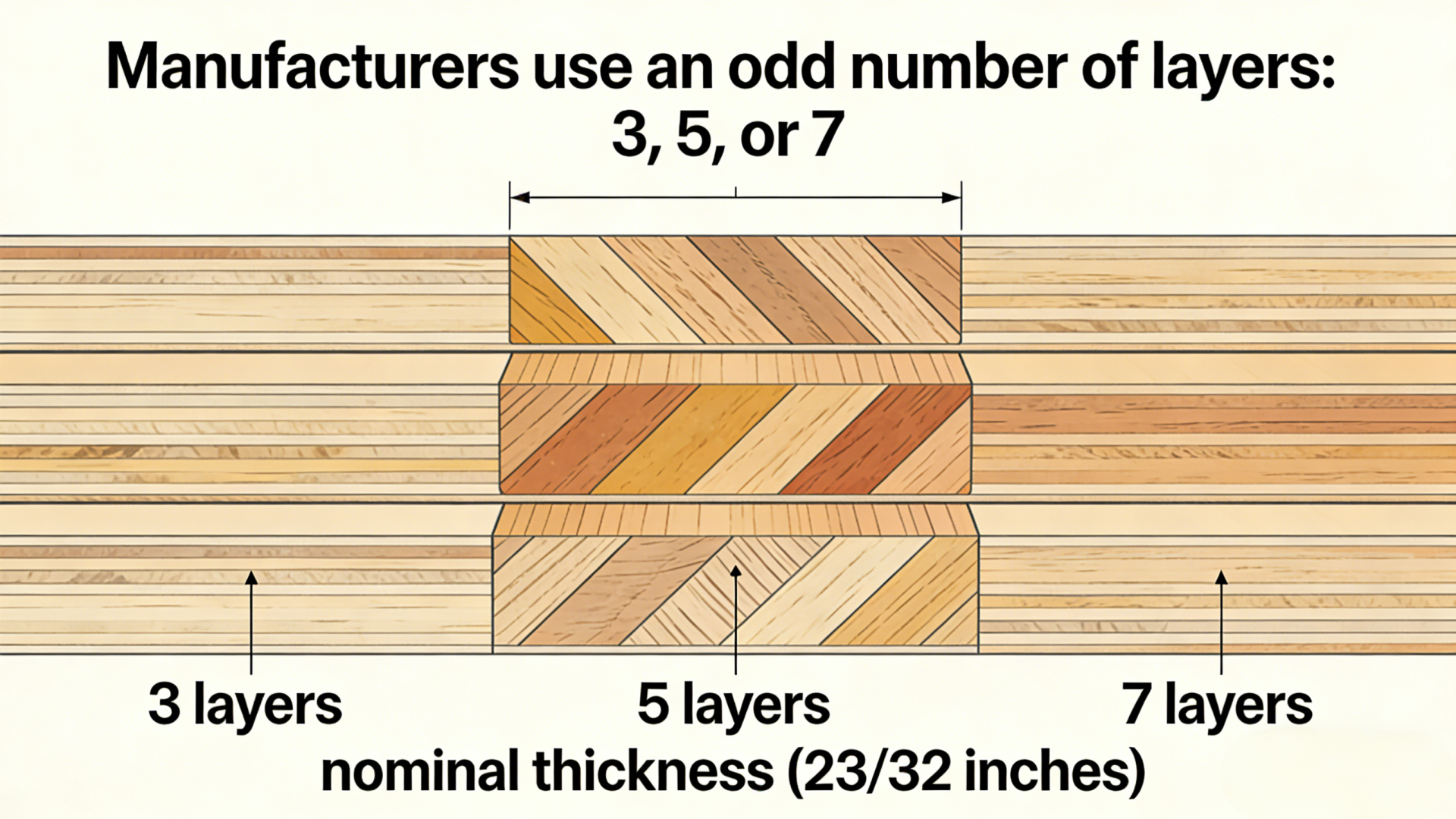

3/4″ plywood originates from its nominal thickness. The actual thickness is approximately 19 millimeters, or 23/32 inches. It is a strong wood panel made from thin layers of wood glued together under high heat. These thin layers typically come from pine, birch, or poplar – all common and reliable choices.

Manufacturers use an odd number of layers: 3, 5, or 7. The wood grain of each layer runs perpendicular to the adjacent layers. This method prevents warping and cracking and increases strength, making it stronger than solid wood.

Image Source:Doubao AI Generated

This is not a new material. Early 3/4″ plywood was used in 19th-century train cars, crates for the 1907 Antarctic expedition, and the interior structures of old ships. Today, its standard size is 4×8 feet, or 48×96 inches. Structural Wood Popular Science magazine calls this size of structural plywood ideal for structural uses, such as wall sheathing, subflooring, and roof panels.

Each layer adds strength: 7-ply plywood is tougher than 3-ply. The thin layers are typically 1-3 millimeters thick. They are tightly bonded together under high heat to form a panel capable of withstanding heavy loads. Simple design, solid materials, and precise dimensions – these characteristics make 3/4″ plywood a preferred material for builders worldwide.

Why 3/4” Plywood Is Essential?

3/4″ plywood is essential because it is strong, durable, suitable for most projects, and meets building standards. It is a top choice for builders and DIYers. It is thicker than other lighter plywood options, so it holds up better without being hard to use.

Plywood Thickness: The Basics

3/4″ plywood measures exactly 23/32 inches or 0.703 inches. This is the industry standard contractors call “three-quarter inch” plywood. Major brands maintain consistent dimensions. It’s compatible with hardware and meets building codes.

The standard sheet size is 4×8 feet or 48×96 inches. Each sheet covers 32 square feet. Key facts to know:

- Weight: 60-75 pounds per 4×8 sheet. Easy to carry, yet strong

- Industry approval: APA – The Engineered Wood Association names it a go-to for homes and businesses

- No gaps: Consistent thickness prevents loose joins, unlike thinner plywood

This mix of size and reliability makes it a solid base for any job.

How Thickness Affects Your Project

The 3/4-inch thickness offers real, data-backed benefits. It can support 40-50 pounds per square foot, making it suitable for flooring. It can span 24-inch joist spacing. As wall sheathing, it can withstand 110 mph winds. For cabinets, it can support over 100 pounds of evenly distributed weight.

Woodworking Network notes this thickness boosts usability too. It cuts cleanly with less splintering. It keeps screws tight over time. It does not warp easily. These small perks make projects sturdier. They last longer and need fewer fixes down the line. This saves time and money for anyone using it.

Common Types of 3/4” Plywood

3/4” plywood has different types, each made for specific projects. They vary in materials, how long they last, and how well they work. This makes them good for jobs from building structures to adding decor. The table below shares their key details, uses, and features, based on industry standards.

| 类型 | Uses | Key Features |

| Softwood Plywood | Roof sheathing, subflooring, outdoor sheds, wall framing, temporary structures | • Made from pine or fir • 60–75 lbs per 4×8 sheet • Affordable and easy to find • Good for structural load-bearing |

| Hardwood Plywood | Cabinets, furniture, interior shelving, decorative millwork, flooring overlays, door panels | • Uses birch, maple or oak • Nice natural grain for visible areas • Holds screws tightly • Resists wear and dents • Great for finished projects |

| Marine Plywood | Boat building, outdoor furniture, bathroom vanities, wet basements, coastal structures | • Waterproof adhesive inside • Fights rot, mold and saltwater • Made from birch or okoume • Withstands 110 mph winds • Handles moisture well |

| Melamine-Faced Plywood | Kitchen cabinets, countertops, retail fixtures, closet built-ins, office furniture | • Scratch and water-resistant surface • Density 610–700 kg/m³ • Easy to clean • No extra finishing needed • Durable for busy areas |

| Poplar Plywood | Interior trim, furniture frames, hidden structural parts, drawer boxes, craft projects | • Light color with straight grain • Easy to cut, sand and paint • Low-cost for hidden parts • Lightweight but strong |

Other Plywood Thickness

1/2″, 5/8″, vs. 3/4″ Plywood

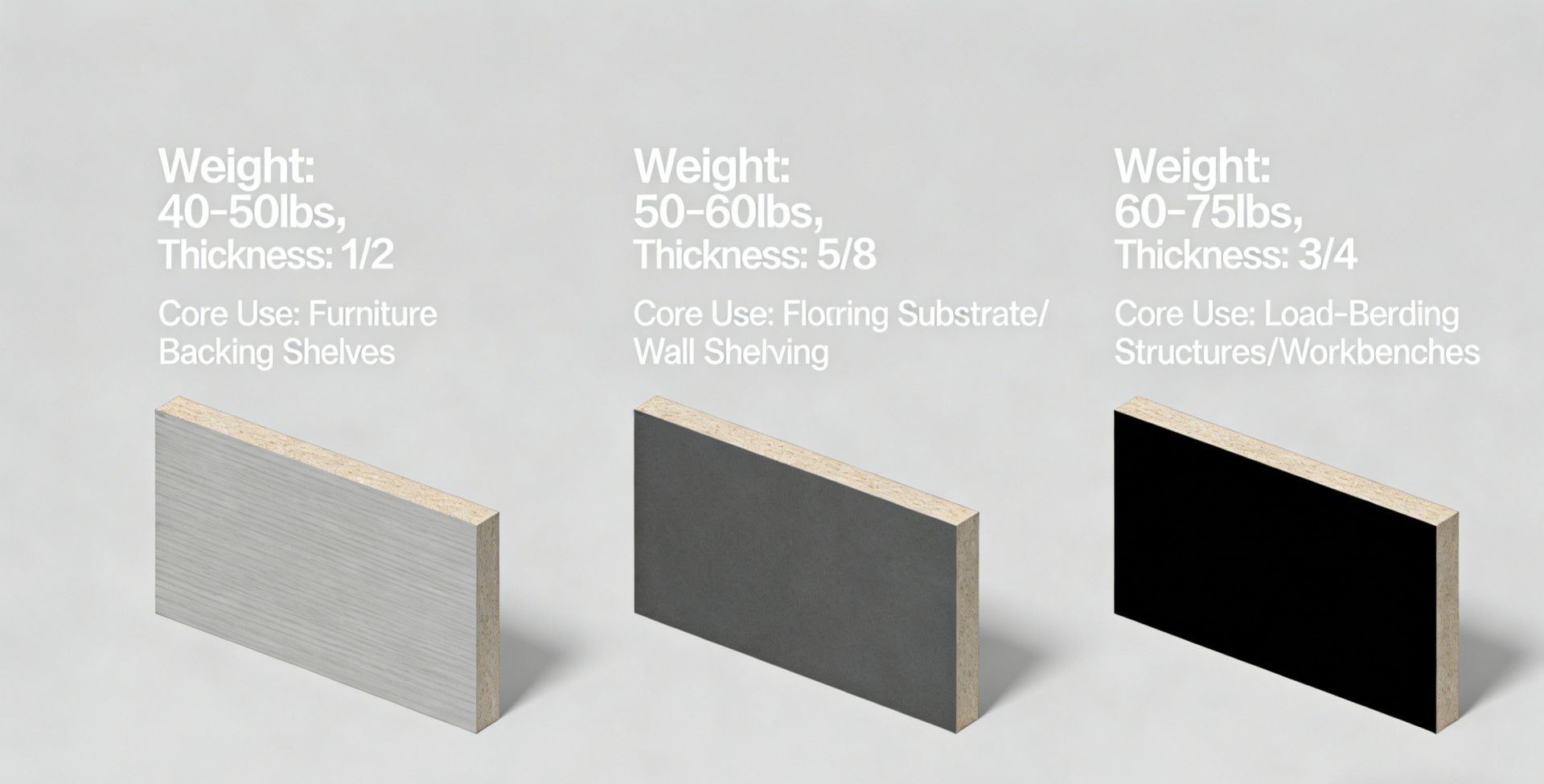

1/2″, 5/8″ and 3/4″ are the three most common plywood thicknesses. They vary a lot in weight, strength and ideal uses, so picking the right one matters for your project success.

Image Source:Doubao AI Generated

1/2″ Plywood

It weighs 40-50 lbs per 4×8 sheet, making it the lightest option. It’s cheap and works well for light interior tasks like small shelves or wall panels, but it can’t handle heavy loads or structural work that needs long-term stability.

5/8″ Plywood

This is the middle option, weighing 50-60 lbs per 4×8 sheet. It’s stronger than 1/2″ plywood but cheaper than 3/4″. It’s a solid pick for wall sheathing or subflooring in small spaces, balancing cost and strength nicely for mid-demand projects.

3/4″ Plywood

At 60-75 lbs per 4×8 sheet, it’s the heaviest and strongest choice. It costs a bit more but lasts longer, handling heavy loads better than thinner alternatives for tough, long-term jobs that need reliable performance.

When to Use 3/4″ Plywood

3/4″ plywood is the top choice for projects that need serious strength and long-lasting durability. It’s the go-to material when you need a sturdy base that won’t warp or fail under pressure. Use it for these key tasks:

- Flooring that supports heavy furniture, appliances or high foot traffic

- Cabinets, shelves and storage units holding lots of weight regularly

- Outdoor builds like sheds, decks, playhouses or garden beds exposed to weather

- Large-scale structural tasks like roof framing, wall sheathing or subflooring for big spaces

- Wet areas such as bathrooms or coastal structures (opt for marine-grade 3/4″ plywood to resist rot and moisture damage)

-1920x1280.jpg)

Image Source:699pic.com

Thinner plywood fits light, low-demand jobs where strength isn’t a top priority. 3/4″ plywood stands out when you need a reliable, tough material that can handle the test of time and heavy use.

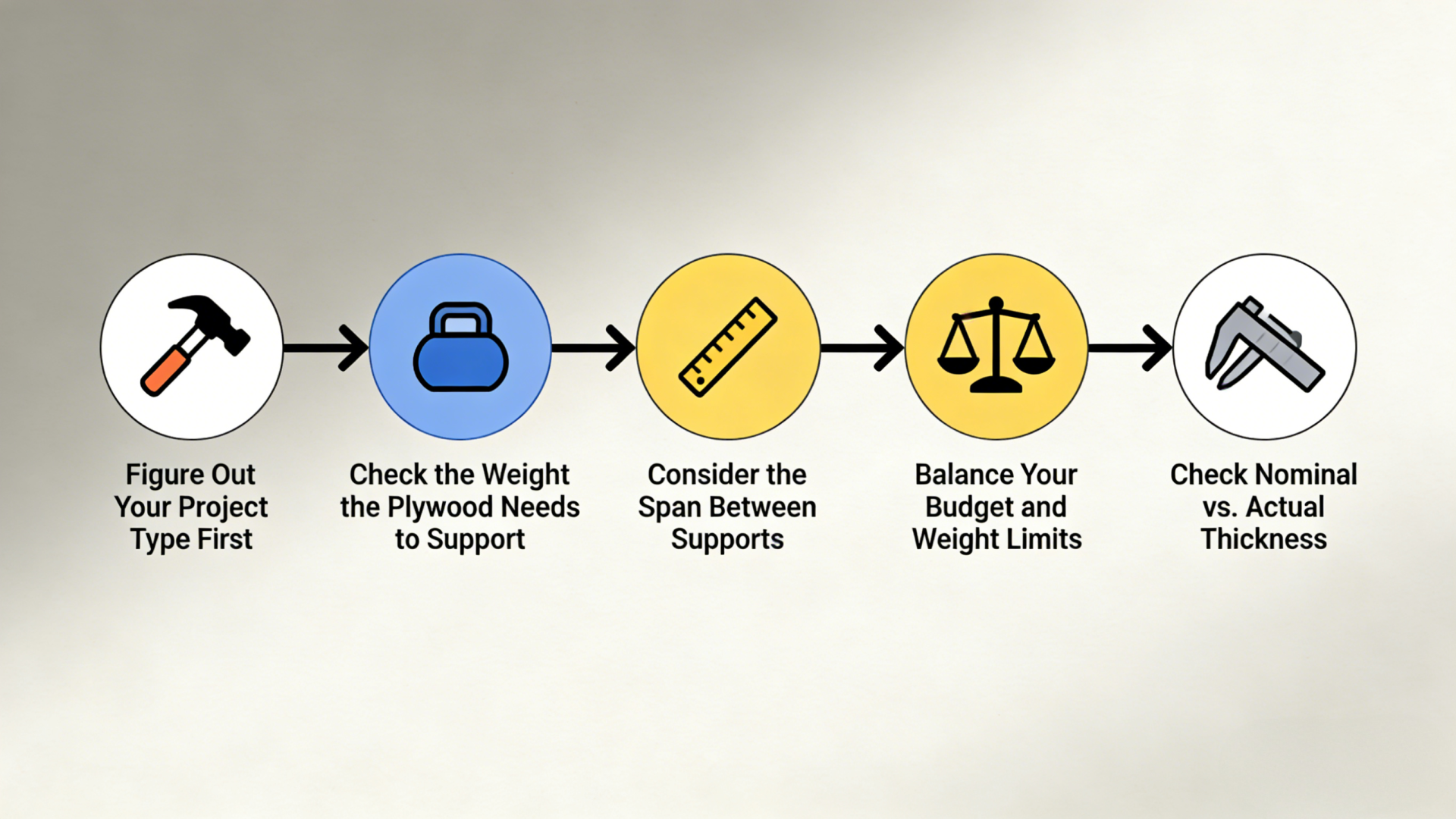

How to Choose the Right Thickness For Your Project

Choosing the right plywood thickness makes your project strong, durable and affordable. Follow these simple steps to pick the best option for your build.

Image Source:Doubao AI Generated

1. Figure Out Your Project Type First

Start by knowing what you want to make. Decorative items like wall panels or cabinet backs only need thin plywood, usually 1/4″ to 1/2″. Furniture pieces like small shelves or cabinet sides work well with medium plywood, 1/2″ to 5/8″. Structural projects like flooring, roofing or outdoor decks need thick plywood of 3/4″ or more to hold up over time.

2. Check the Weight the Plywood Needs to Support

Thicker plywood holds more weight than thin options. Sort your project by how much weight it will carry:

- Light-duty uses (drawer bottoms, decorative trim): Thin plywood works perfectly

- Medium loads (bookshelves with light boxes): Medium-thickness plywood is ideal

- Heavy loads (subfloors with appliances, tool cabinets): Thick plywood is a must-have

3. Consider the Span Between Supports

Span means the distance between the beams holding the plywood. Short spans (less than 2 feet) don’t stress the wood much. Thinner plywood works here without sagging. Longer spans (2 feet or more) need thicker plywood. It keeps its shape and won’t bend over time.

4. Balance Your Budget and Weight Limits

Thicker plywood costs more and weighs more than thin kinds. Keep these tips in mind for smart picks:

- Save money or cut weight: Use thin plywood for non-structural parts like cabinet backs

- Prioritize strength: Spend a little more on thicker plywood for load-bearing spots like subfloors

5. Check Nominal vs. Actual Thickness

The labeled thickness of plywood is not always the real thickness. Manufacturers sand the wood during production. This makes the final size a little smaller. For projects that need exact fits, measure the plywood yourself before cutting. Don’t just rely on the label.

Always match the plywood thickness to your project’s needs. Thinner options work great for light, decorative tasks. Thicker ones keep structural projects stable and long-lasting.

结论

3/4″ plywood stands out for its strength, durability, and versatility—making it a top choice for builders and DIYers. Its layered design avoids warping, and it works for structural jobs, furniture, and outdoor projects. By matching thickness to your project type, weight needs, and budget, you’ll get long-lasting results. From subflooring to cabinets, 3/4″ plywood delivers reliability that thinner options can’t match. Use this guide to make smart choices and ensure your project’s success.

FQA

- Can 3/4″ plywood be used outdoors without treatment?

No. Regular 3/4″ plywood isn’t waterproof. For outdoor use, choose marine-grade 3/4″ plywood (with waterproof glue) or treat regular plywood with weatherproof sealant to prevent rot.

- How do I cut 3/4″ plywood cleanly without splintering?

Use a sharp circular saw or jigsaw with a fine-tooth blade. Place the plywood’s finished side down when cutting, and mark straight lines with a ruler. Supporting the wood fully also reduces splintering.

- Is 3/4″ plywood safe for children’s furniture (like playhouses)?

Yes. It’s strong enough to hold kids’ weight and resists wear. Opt for hardwood or poplar 3/4″ plywood (smooth, low-VOC) and sand edges to avoid splinters.

- Can 3/4″ plywood be painted or stained easily?

Absolutely. Sand the surface lightly first to help paint/stain adhere. Plywood with a smooth face (like hardwood or melamine-faced) needs less sanding. Stain shows the wood grain, while paint covers it for a uniform look.

进一步了解我们的产品?

立即联系