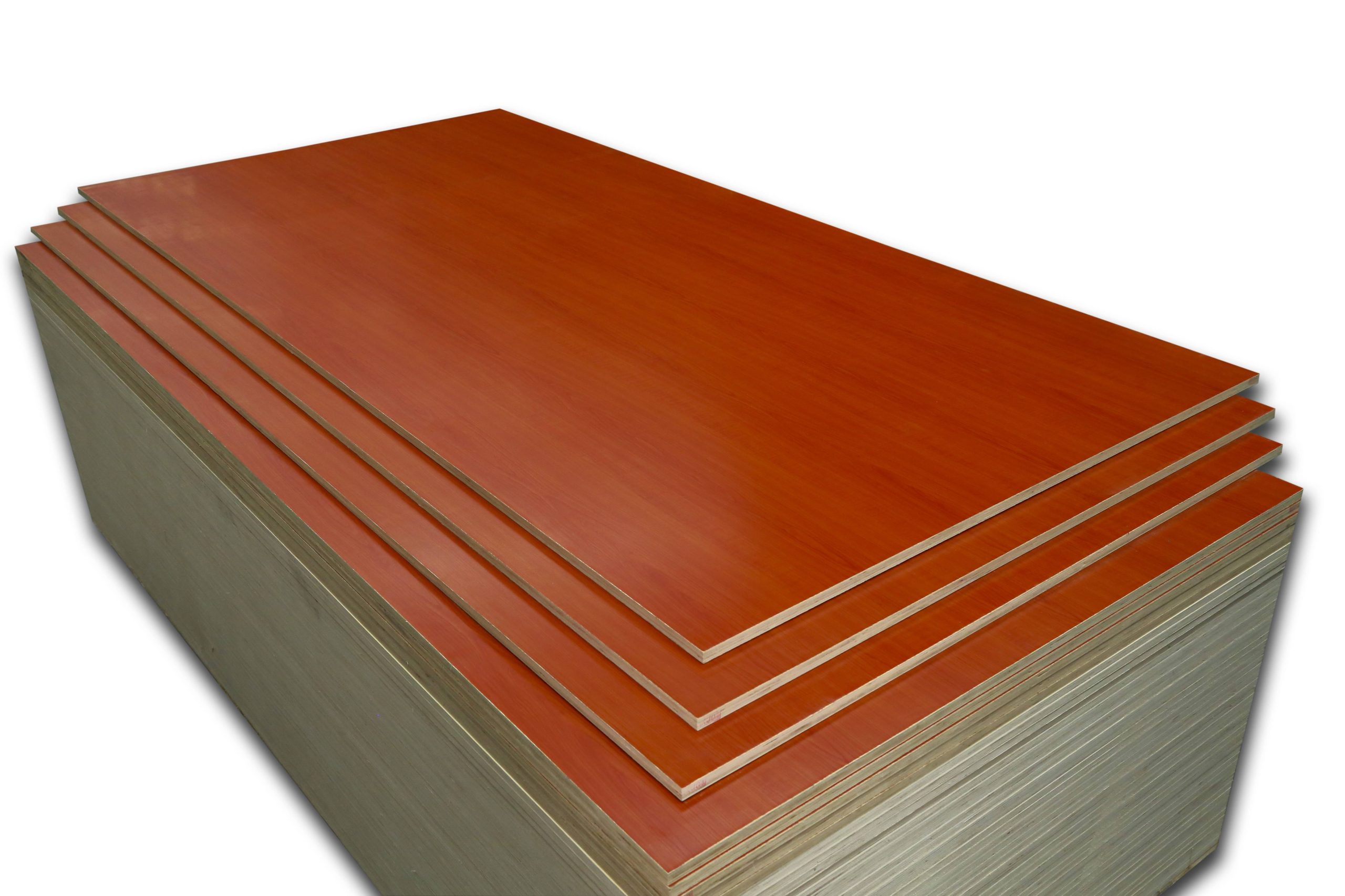

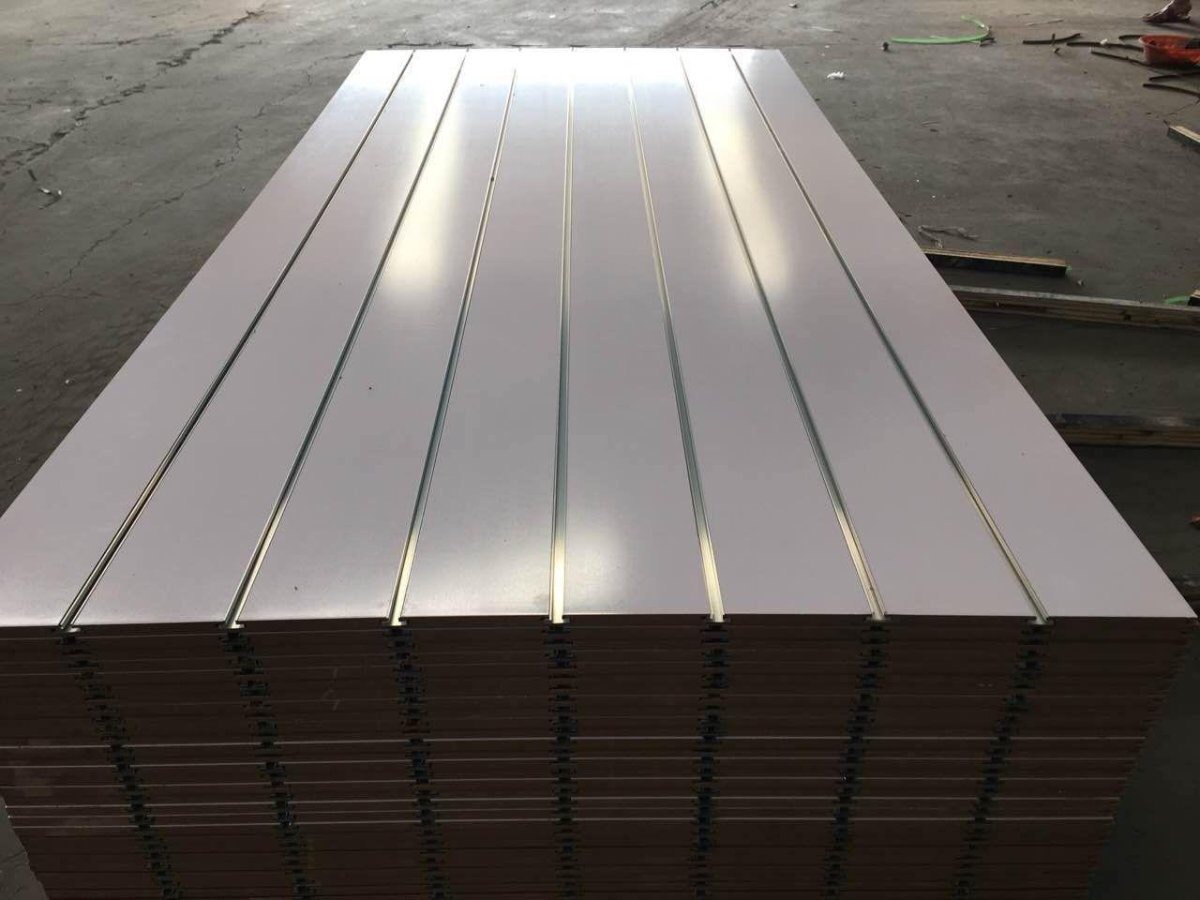

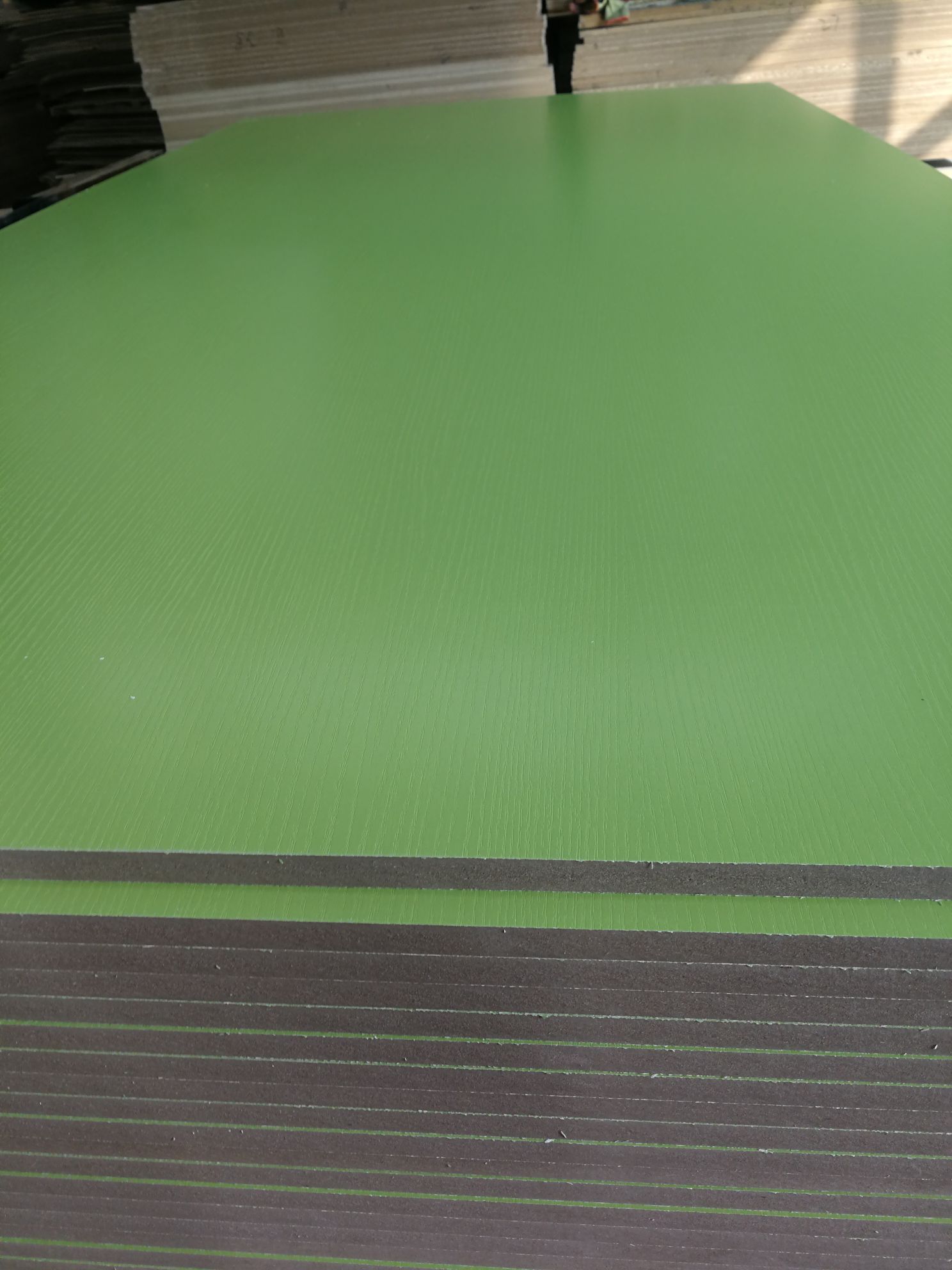

MDF melamínico comum e impermeável

Descrição

O MDF, também conhecido como painel de fibras, é um painel à base de madeira fabricado com resina lignocelulósica ou outros adesivos adequados. Os adesivos e/ou aditivos podem ser aplicados durante o processo de fabrico. O MDF tem as vantagens de um material uniforme, uma pequena diferença na resistência longitudinal e transversal, não é fácil de fissurar e tem uma vasta aplicação. São necessários cerca de 2,5 a 3 metros cúbicos de madeira para produzir 1 metro cúbico de MDF, que pode substituir 3 metros cúbicos de madeira serrada ou 5 metros cúbicos de toros. O desenvolvimento da produção de painéis de fibras é uma forma eficaz de utilizar de forma abrangente os recursos de madeira. O MDF melamínico é um tipo de MDF sofisticado laminado com papéis de resina melamínica que inclui dezenas de cores e desenhos e é também à prova de água e anti-riscos.

Detalhes

Processo de produção

PREPARAÇÃO DE MATÉRIAS-PRIMAS

- Recolher matérias-primas como toros de madeira, resíduos de serração e madeira reciclada.

- Remover as impurezas (por exemplo, metal, pedras) e descascar os toros.

- Cortar os materiais em pequenas lascas (2-5 cm de comprimento) com uma picadora.

PRODUÇÃO DE FIBRASG

- Vaporizar as aparas de madeira num digestor a 160-180°C durante 20-30 minutos para amolecer a lenhina.

- Triturar as aparas amolecidas em fibras finas utilizando um desfibrador (processo mecânico ou termo-mecânico).

SECAGEM DE FIBRAS

- Secar as fibras num secador rotativo para reduzir o teor de humidade para 8-12%.

- Separar e peneirar as fibras secas para remover as partículas sobredimensionadas.

COLAGEM E APLICAÇÃO DE ADITIVOS

- Misturar as fibras com resina sintética (principalmente resina de ureia-formaldeído) numa proporção de 8-12% de peso de fibra.

- Adicionar emulsão de cera (para resistência à água) e agentes de cura conforme necessário.

- Assegurar uma distribuição uniforme dos adesivos através de um sistema de mistura.

FORMAÇÃO DE TAPETES

- Transportar a mistura de fibras e resina para uma máquina de moldagem.

- Formar um tapete solto contínuo e uniforme com espessura e densidade controladas.

PRÉ-IMPRESSÃO

- Comprimir o tapete solto numa máquina de pré-prensagem para reduzir o volume e melhorar a estabilidade.

- Formar uma placa semi-endurecida para facilitar o manuseamento em processos subsequentes.

PRENSAGEM A QUENTE

- Transferir a placa pré-prensada para uma prensa quente de várias camadas.

- Aplicar alta temperatura (180-220°C) e pressão (2,5-4 MPa) durante 3-10 minutos.

- O calor cura a resina e a pressão une as fibras numa placa sólida.

ARREFECIMENTO E CORTE

- Arrefecer as placas prensadas a quente até à temperatura ambiente, utilizando grelhas de arrefecimento ou ventoinhas.

- Cortar os bordos para obter dimensões normalizadas (por exemplo, 2440×1220 mm) com serras.

LIXO

- Lixe ambas as superfícies das tábuas utilizando máquinas de lixar com várias cabeças.

- Obter suavidade e espessura precisa (normalmente 3-30 mm).

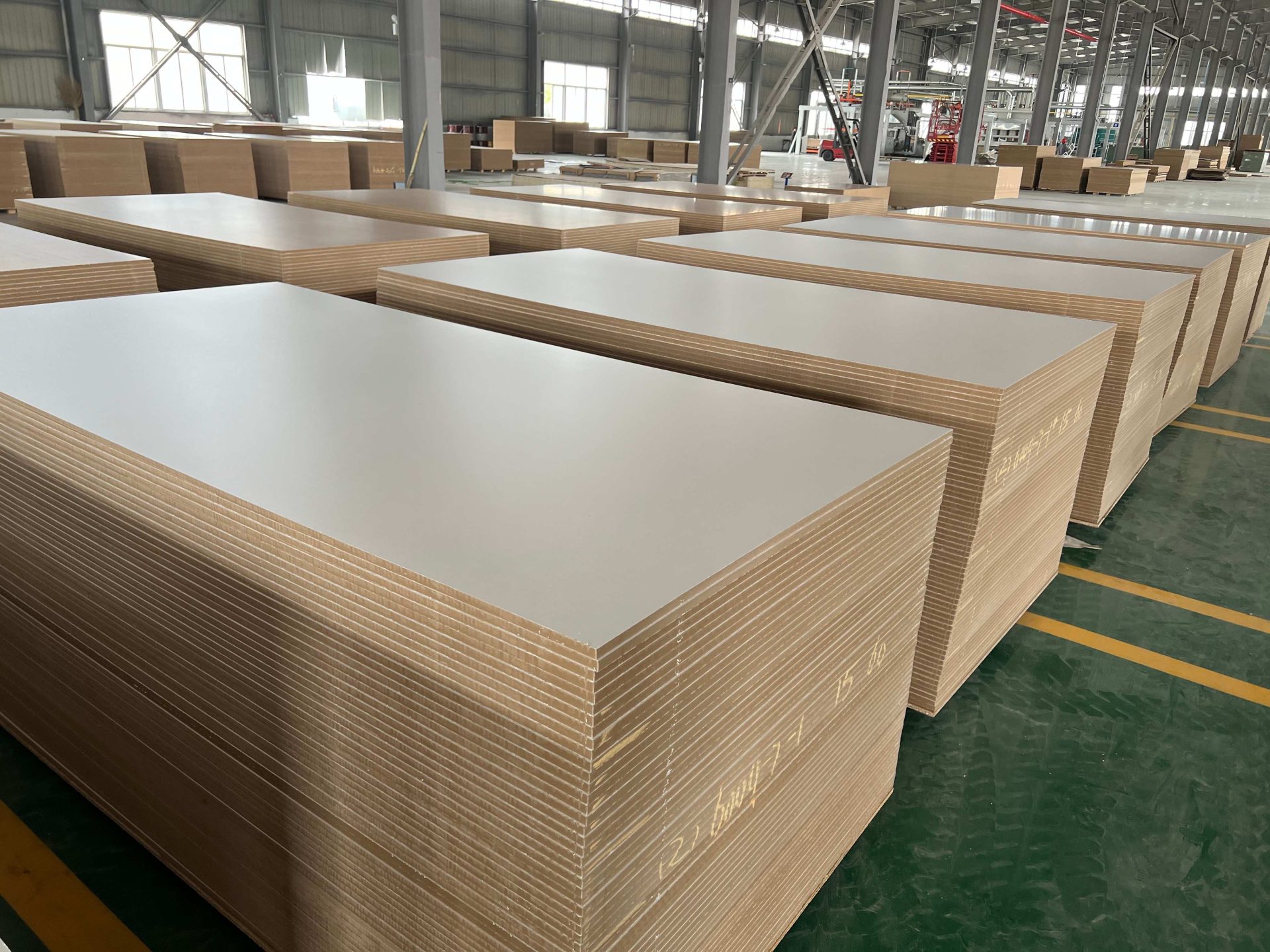

INSPECÇÃO DA QUALIDADE E EMBALAGEM

- Inspecionar as tábuas para detetar defeitos (por exemplo, fissuras, densidade irregular, imperfeições da superfície).

- Classificar os quadros qualificados com base em normas de qualidade.

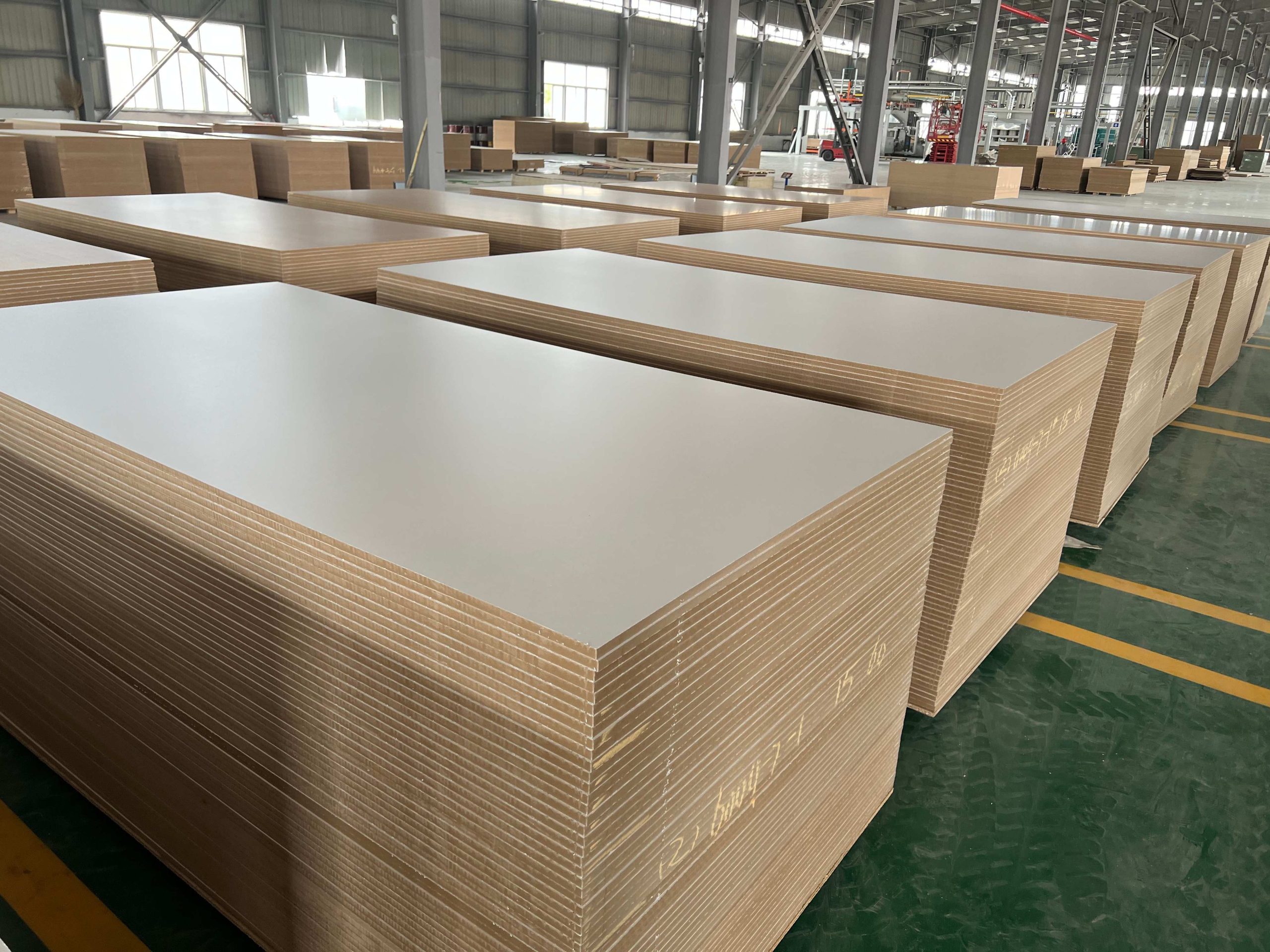

- Empilhar e embalar as placas para armazenamento ou expedição.

Controlo de qualidade e embalagem