MDF em bruto de alta resistência

Descrição

High Strength Raw MDF significa Medium Density Fiberboard (painel de fibras de média densidade). O painel de fibras de média densidade é feito de fibras vegetais, aplicado com resina de ureia-formaldeído ou outras resinas sintéticas, e prensado sob condições de aquecimento e pressão para formar uma placa com uma densidade na faixa de 0,50 ~ 0,88g / cm3. Outros também podem ser adicionados. Aditivos adequados para melhorar as propriedades da placa. Não há consumo de água no processo de produção, e pode ser reciclado.

O MDF, também conhecido como painel de fibras, é um painel à base de madeira fabricado com resina lignocelulósica ou outros adesivos adequados. Os adesivos e/ou aditivos podem ser aplicados durante o processo de fabrico. O MDF tem as vantagens de um material uniforme, uma pequena diferença de resistência longitudinal e transversal, não é fácil de fissurar e tem uma vasta aplicação. São necessários cerca de 2,5 a 3 metros cúbicos de madeira para produzir 1 metro cúbico de MDF, que pode substituir 3 metros cúbicos de madeira serrada ou 5 metros cúbicos de toros. O desenvolvimento da produção de painéis de fibras é uma forma eficaz de utilizar de forma abrangente os recursos de madeira.

Camada protetora de alta resistência, não só elevada resistência a riscos, elevada resistência ao desgaste, mas também elevada resistência à humidade. A forma, a cor e a textura da superfície do MDF criam um espaço ilimitado para o design. O pacote de pó fechado reduz grandemente a emissão de formaldeído residual no MDF, e as bactérias não são fáceis de crescer. O MDF pode, ao mesmo tempo, remover eficazmente o formaldeído do painel, cumprindo as normas de proteção ambiental. Consegue efetivamente poupar energia e reduzir as emissões.

Detalhes

Processo de produção

ARMAZENAMENTO DE MATÉRIAS-PRIMAS

Dispomos de vários armazéns para armazenar todas as nossas matérias-primas, tais como folheado de choupo, folheado de madeira dura, Sapelli/Bintangor/Okoume/Pencil Cedar/Pine Face/Back, etc. Assim que as novas matérias-primas são entregues nos nossos armazéns, os nossos trabalhadores inspeccionam-nas e colocam as matérias-primas de diferentes graus em diferentes armazéns.

PRÉ-TRATAMENTO DE MATÉRIAS-PRIMAS

Uma vez iniciada a produção, os nossos trabalhadores procedem ao pré-tratamento das matérias-primas, incluindo a junção dos lados, a colagem.

MONTAGEM DE FOLHEADOS

Os nossos trabalhadores montam as lâminas de madeira uma camada por camada na linha de montagem. Por exemplo, o 18MM será composto por 11 camadas de lâminas de madeira.

PLACAS EM BRUTO PRÉ-IMPRESSÃO

Após o processo de montagem do folheado, todas as placas em bruto precisam de ser pré-pressionadas por uma máquina de prensagem a frio. Para que as placas em bruto possam ser moldadas em contraplacado em bruto. Este processo necessita de pelo menos 2 horas.

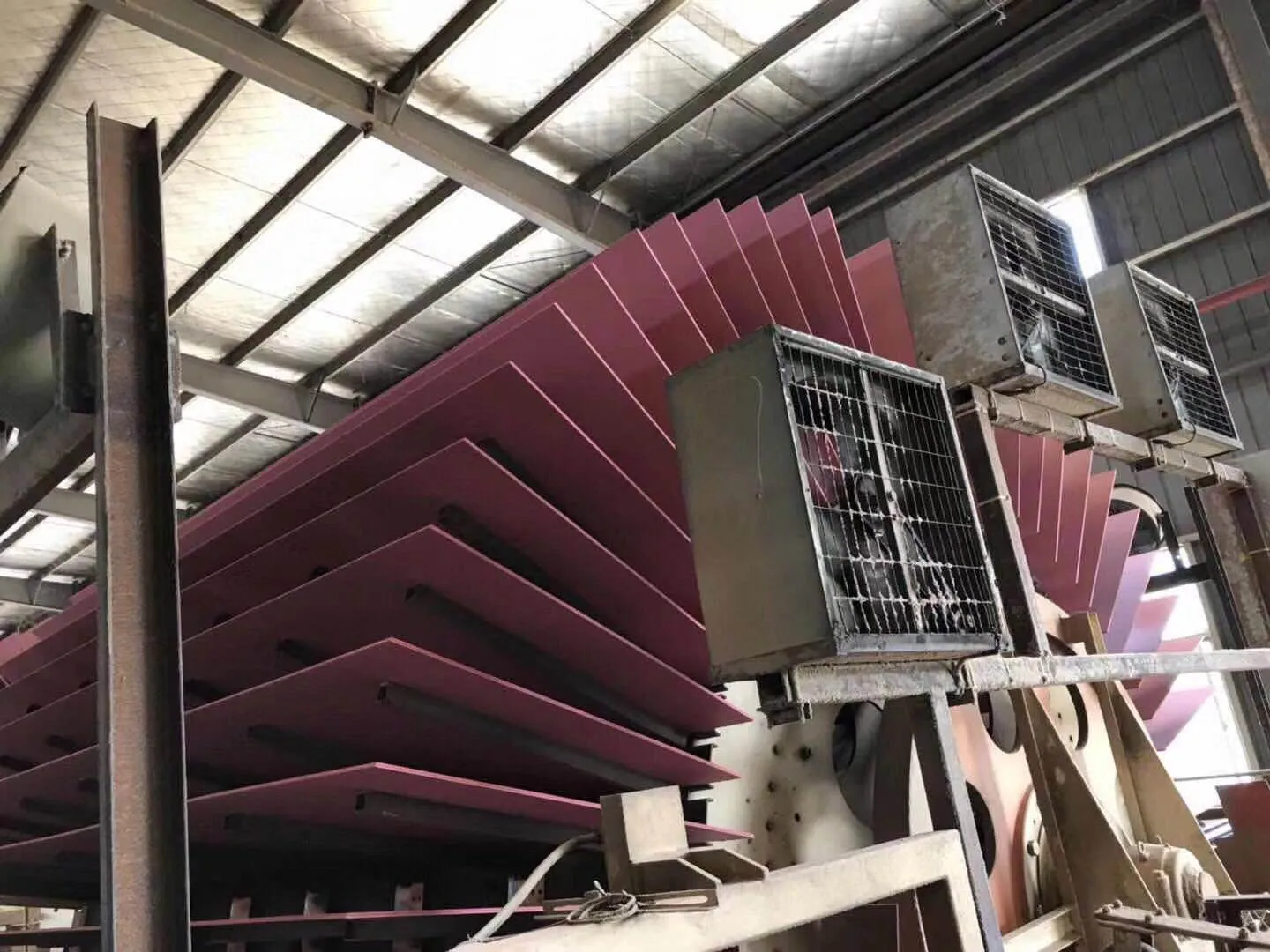

PRENSA A QUENTE DE MADEIRA DE PINHO EM BRUTO

O contraplacado em bruto moldado será laminado por uma máquina de prensagem a quente. Este processo necessita de pelo menos 1 hora. Após a prensagem a quente, a ligação do contraplacado em bruto será forte.

REPINTURA E BETUMAÇÃO DE MADEIRA EM BRUTO

Este processo destina-se a preencher as lacunas na superfície do contraplacado em bruto.

LIXAGEM DE MADEIRA EM BRUTO

Colocar o contraplacado em bruto na máquina de lixar. Depois de lixar, a superfície do contraplacado em bruto fica lisa e a espessura também fica uniforme.

MONTAGEM DO FOLHEADO FACE/VERSO

O contraplacado em bruto é colado em primeiro lugar. Em seguida, os trabalhadores colocam o folheado de face/verso, como Sapelli /Bintangor/Okoume/Pencil Cedar, em ambos os lados do contraplacado em bruto.

IMPRENSA FRIA

Após o processo de montagem do folheado de face/verso, o contraplacado será novamente colocado na máquina de prensagem a frio. Para que o folheado de face/verso se una inicialmente ao contraplacado em bruto. Este processo necessita de pelo menos 1 hora.

PRENSA A QUENTE DE MADEIRA COMPENSADA LAMINADA

Este processo necessita de pelo menos 30 minutos. Após a segunda prensagem a quente, o folheado da face e do verso ligar-se-á fortemente ao contraplacado em bruto.

CORTE E POLIMENTO

Toda a madeira compensada será cortada em tamanho padrão como1220X2440MM. Em seguida, o contraplacado será polido para tornar a face/verso liso.

INSPECÇÃO E EMBALAGEM

Inspecionar as placas para detetar defeitos (por exemplo, fissuras, densidade irregular, imperfeições da superfície). Classificar as placas qualificadas com base em padrões de qualidade. Empilhar e embalar as placas para armazenamento ou expedição.

Controlo de qualidade e embalagem