설명

기존 드롭 천장 타일의 모든 기능을 훨씬 적은 무게로 제공하도록 설계되었습니다. 깃털처럼 가벼운 구조로 설치가 간편하고 청소가 쉬우며 얼룩 방지, 방수, 먼지 방지, 환경 친화적입니다! 설치가 빠르고 이보다 더 쉬울 수는 없습니다. 벽 클래딩으로도 사용할 수 있습니다.

세부 정보

유형

긴 연속 스트립/정사각형

Surface

인쇄/핫 스탬핑/라미네이션

너비

60mm,100mm,200mm,250mm,300mm,400mm,600mm

두께

4mm,5mm,6mm,7mm, 8mm,8.5mm,9mm

PVC 콘텐츠

35%,40%,45%,50%,55%

생산 프로세스

원료 혼합

고속 믹서를 사용하여 PVC 수지, 안정제, 충전제 및 첨가제를 정확한 비율로 혼합하여 균일성을 보장합니다.

핫멜팅

혼합 재료를 압출기에서 180~200°C로 가열하여 균일한 용융 덩어리로 만듭니다.

압출 성형

용융된 재료를 다이를 통해 강제로 밀어 넣어 단면이 고정된 연속 패널 블랭크를 형성합니다.

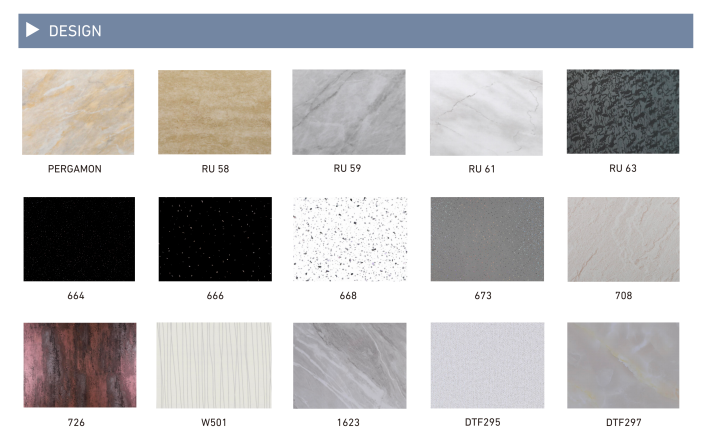

표면 인쇄/라미네이션

롤러 인쇄를 통해 장식 패턴을 적용하거나 미관을 위해 PVC 필름으로 라미네이팅합니다.

냉각 및 크기 조정

패널을 물로 식혀 치수를 안정화하여 직진성과 정확한 두께를 보장합니다.

길이에 맞게 자르기

정밀 톱으로 연속 패널을 지정된 길이(예: 2440mm)로 자릅니다.

포장

패널을 PE 필름으로 감싸고 팔레트에 포장하여 긁힘과 습기로부터 보호하세요.

로딩 및 배송

팔레트화된 제품을 컨테이너에 적재하여 안전하게 운송할 수 있도록 고정합니다.

품질 관리 및 포장

당사는 지속적인 배송 전 검사 시스템을 갖추고 있습니다. 주문이 확정된 후 즉시 검사 프로세스가 시작됩니다. 원재료의 등급과 종류, 가공 방법, 검사 및 포장 세부 사항은 공장 관리자에게 알려드립니다.

지금 문의

공장 및 인증서

당사는 지속적인 배송 전 검사 시스템을 갖추고 있습니다. 주문이 확정된 후 즉시 검사 프로세스가 시작됩니다. 원재료의 등급과 종류, 가공 방법, 검사 및 포장 세부 사항은 공장 관리자에게 알려드립니다.

지금 문의