설명

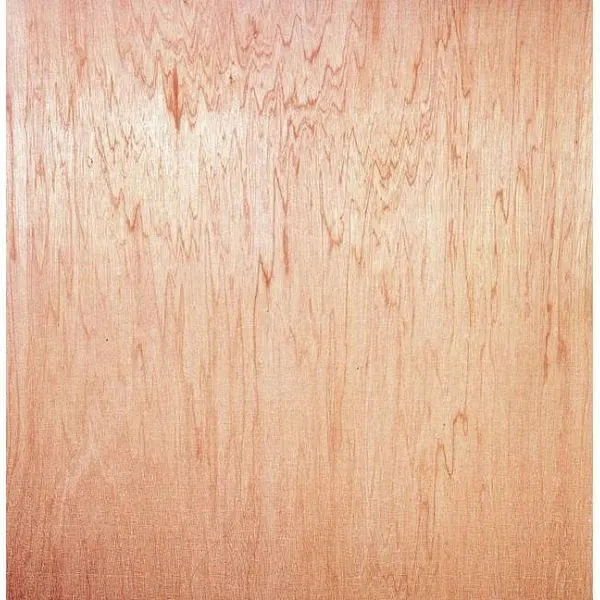

상업용 합판 일반적으로 합판의 등급을 나타냅니다. 내습 합판이 어느 정도의 습기와 습기를 견딜 수 있는 것은 사실이지만. 상업용 합판은 실내 장식, 실내 가구, 포장 장식 등에 가장 널리 사용되는 합판 유형입니다.

빙탕고르라고 잘못 표기되기도 하는 빈탕고르(칼로필룸의 상품명)는 붉은색 경재의 일종입니다. 로터리 컷 빈탕고르 베니어는 나뭇결이 아름답습니다. 이것이 빈탕고르가 합판의 일반적인 앞면/뒷면 베니어인 이유입니다. 빈탕고르 합판은 나뭇결이 좋아서 가구 제작 및 장식에 적합합니다. 일반적으로 유럽 및 미국 구매자는 B / BB, BB / CC 등급 (또는 유사한 등급)의 Bintangor 합판을 선호합니다. B/BB, BB/CC 빈탕고르 합판의 앞면/뒷면 베니어는 깨끗하고 개방형 결함이 없습니다. 빈탕고르 합판은 가구 제작 및 장식에 좋은 선택입니다.

세부 정보

생산 프로세스

원자재 보관

포플러 베니어, 원목 베니어, 사펠리/빈탕고르/오쿠메/펜슬 시더/파인 페이스/백 등 모든 원자재를 보관할 수 있는 여러 창고가 있습니다. 새로운 원자재가 창고에 입고되면 작업자가 모든 원자재를 검사하고 다른 등급의 램 자재를 다른 창고에 배치합니다.

원자재 전처리

생산이 시작되면 작업자는 측면 조인트, 접착 등 원자재를 전처리합니다.

베니어 조립

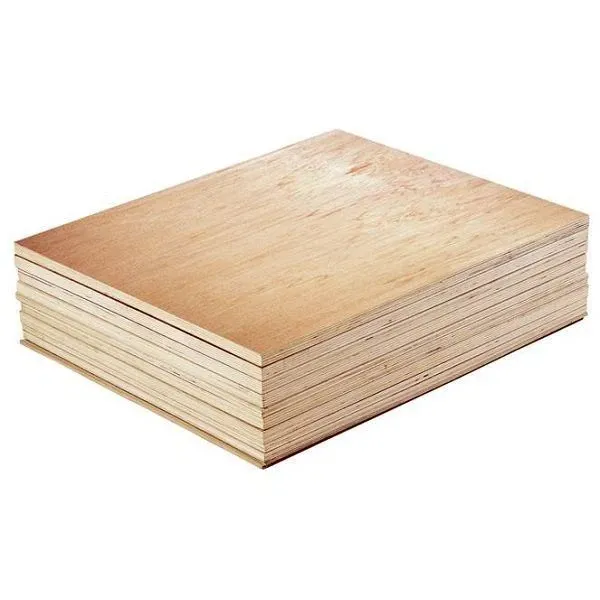

작업자는 조립 라인에서 목재 베니어를 한 층씩 조립합니다. 18mm와 같이 11겹의 우드 베니어로 구성됩니다.

원판 프리프레스

베니어 조립 공정 후, 모든 원판은 냉간 프레스 기계로 프리프레싱해야 합니다. 그래야 원판 합판의 모양을 만들 수 있습니다. 이 과정은 최소 2시간이 필요합니다.

원목 핫 프레스

성형된 원판 합판은 핫 프레스 기계로 적층됩니다. 이 과정은 최소 1시간이 필요합니다. 핫 프레스 후 원시 합판 결합이 강해집니다.

원목 재패치 및 퍼티링

이 과정은 원판 합판 표면의 틈을 메우는 과정입니다.

원목 샌딩

합판을 샌딩 머신에 넣습니다. 샌딩 후 합판 표면이 매끄러워지고 두께도 균일 해집니다.

페이스/백 베니어 어셈블리

원목 합판을 먼저 접착합니다. 그런 다음 작업자가 사펠리/빈탕고르/오쿠메/펜슬 시더와 같은 페이스/백 베니어를 원목 합판 양쪽에 배치합니다.

콜드 프레스

페이스/백 베니어 조립 공정이 끝나면 합판을 다시 냉간 프레스 기계에 넣습니다. 이렇게 하면 페이스/백 베니어가 처음에 원합판과 접착됩니다. 이 과정은 최소 1시간이 필요합니다.

라미네이트 파이우드 핫 프레스

이 과정은 최소 30분이 필요합니다. 두 번째 핫 프레스 후, 페이스/백 베니어는 원판 합판과 강하게 결합됩니다.

절단 및 연마

모든 합판은 1220X2440MM과 같은 표준 크기로 절단됩니다. 그런 다음 합판을 연마하여 앞면 / 뒷면을 매끄럽게 만듭니다.

검사 및 포장

보드에 결함(예: 균열, 고르지 않은 밀도, 표면 결함)이 있는지 검사합니다. 품질 표준에 따라 적격 보드를 등급을 매깁니다. 보관 또는 배송을 위해 보드를 쌓고 포장합니다.

품질 관리 및 포장