Plywood Grades: A Simple Guide to Types and Applications

Understanding plywood grades is crucial when choosing the right plywood for your project. The A-D plywood grading system shows the quality and characteristics of the front and back surfaces of the plywood panel.

The A-D grading system ranks the grade using letters, from A to D. Grade A is the highest quality, with a smooth and uniform surface, free of defects. Usually, two-letter combinations such as AC are used to define the quality of face and back veneers of the plywood panel. The first letter indicates the face veneer, and the second letter shows the back veneer. Sometimes, a suffix like X in “CDX” is added to show the type of glue used to make the panel moisture resistant.

This article is intended to help you understand more about plywood. It focuses on all you need to know about plywood, from the standard gradings of softwood and hardwood up to specialty grades. We also prepared a project-matching table to help you decide which grade is right for your project. Other plywood related concepts, such as differences between CDX and ACX, are also explained.

Understanding the Soft Wood Grading System

The plywood grading system of softwood is a standardized system that is visually determined by the quality and appearance of the face and back veneers. Each plywood panel has a face and a back veneer, which are graded individually using letters from A(the best) up to D (the worst). The grade depends on the count and scale of the noticeable defects or knots, patches, or splits.

In the plywood grading system, the face veneer and back veneer are usually given different grades. To show this, we use the two-letter combination marks (such as AC, BC, and CD). The first letter indicates the face veneer, and the second letter indicates the back veneer. This two-letter combination mark is directly proportional to the look, price, and optimal use of the panel.

Below are the explanations of different grades of plywood, including their appearance features, advantages, and applications:

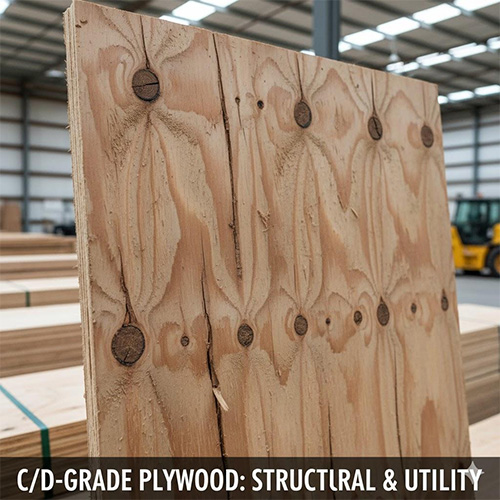

Grade A

Grade A is the top grade of softwood plywood, with a clean sanded surface without defects such as knots, splits, and patches. Because of its high quality and flawless surface, grade A is more expensive than other softwood grades. It is the best choice for projects where appearance and visibility are important.

The face veneer of Grade A plywood has a uniform, consistent color along the whole panel. The surface is free of knots, splits, or patches, and repairs are nearly invisible. Grade A plywood needs little preparation because it is already sanded.

Grade A plywood is used for fine furniture, high-end cabinetry, casework, architectural millwork, and built-in shelving.

Grade B

Grade B plywood has a good-quality surface with some imperfections, such as small, tight knots (usually less than 1 inch) and well-fitting patches. Grade B is a little less smooth than Grade A, but it can still be used for most indoor projects where appearance is important.

The face veneer is smooth and uniform, but a few imperfections are permitted. Grade B can include small, sound knots and well-made, tight-fitting patches or fillers that blend with the surface.

Grade B common applications include shelving, moderate-quality furniture, painted cabinetry, and general millwork.

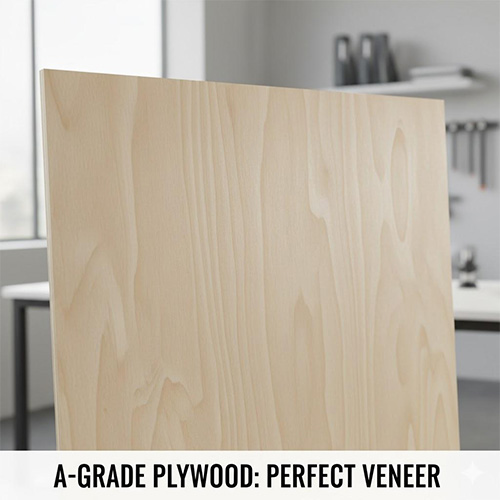

Grade C

Grade C is a middle-grade plywood with larger defects, many of which are not repaired. Grade C allows visible knots, tight slits, unrepaired holes, or frequent patches. This grade is most appropriate in the construction or utility work where the wood is covered.

The knots may go up to 1.5 inches, and the splits or voids are common. Even if the repairs are made, they usually leave a rough texture. Grade C is not as smooth or uniform as Grade A or B, but it is strong and functional for structural purposes.

Grade C common uses include subfloors, wall sheathing, roof decking, and base layers in construction.

Grade D

Grade D is the lowest grade of plywood, loaded with knots, splits, and patches. Huge defects are common, and repairing is not a priority. Grade D allows for larger knots over 2.5 inches (6.4 cm), frequent voids, and unpatched defects. This makes it unsuitable for work where the surface will be visible.

Grade D plywood’s main advantage is cost. Grade D plywood is commonly used in underlayment, rough construction, packaging , and budget constructions.

What Double Letters Mean (AC, BC, CD, etc.)

In the plywood grading system, the first letter represents the face veneer grade, and the second letter refers to the back veneer grade. Consider the AC plywood, where A means Grade A face veneer, and C means Grade C back veneer.

The following table shows the commonly used double letter combinations, together with their short explanations:

| Grade | Face

(first letter) |

Back

(second letter) |

Use it for |

| AC | Smooth, almost flawless | Visible knots and patches | Furniture, cabinetry, shelving and painted panels. |

| BC | Smooth with minor flaws | More knots and patches | Cabinets, interior paneling, shelving where only one side is visible. |

| CD ( also called CDX) | Rougher with knots and patches | Rough, many defects, unfinished | Subfloors, wall sheathing, rock decking, and utility work |

| AD or BD | Smooth or fairly smooth (A/B) | Rough and unfinished (D) | Projects where only one face needs to look clean (cabinet backs, shelving interiors, and built-in drawers) |

What are Exposure Ratings of Plywood?

Exposure ratings are a measure of the resistance of plywood to moisture and weather. They indicate whether a panel is suitable for indoor use only, temporary outdoor exposure, or permanent outdoor use. You can usually find the exposure rating printed on the plywood label or stamped on the panel itself.

Common exposure ratings are exposure 1 and exterior ratings:

- Exposure 1: It means that the plywood can withstand temporary moisture during construction, but is not suitable for permanent outdoor use.

- Exterior: It indicates that the plywood is designed for permanent exposure to weather and moisture. Exterior-rated plywood is usually made with exterior-grade glue to resist water and humidity.

What Does “X” in CDX Stand For?

The “X” in CDX stands for “Exterior.” In CDX, “X” denotes the plywood’s exposure rating, indicating it is bonded with exterior-grade adhesive. This glue gives the panel moisture-resistant properties, meaning it can handle temporary exposure, like rain, during construction.

But exterior-grade adhesive is not completely waterproof; prolonged or constant water exposure can still damage the panel.

What is Hardwood Plywood?

Hardwood plywood is a type of plywood made from decorative hardwood veneers such as oak, birch, or walnut. Unlike softwood plywood, Softwood is mainly used for interior projects where the appearance of the veneer is important, offering a smooth and attractive surface.

Hardwood plywood is graded using standards established by HPVA (Hardwood Plywood and Veneer Association). The grades are indicated by letters (A-D) for the back veneer and a number (1-4) for the face veneer.

This type of plywood is commonly used for high-end furniture, cabinetry, and interior millwork. Hardwood plywood combines both strength and visual appeal.

Common hardwood plywood grades

The following are common hardwood plywood grades according to HPVA standards:

- A1: Both face (A) and back (1) are of the highest veneer quality. Both sides are free from defects, offering a smooth, uniform appearance. A1 grade is ideal for projects where both sides of the plywood will be visible, such as cabinet doors, premium doors, and architectural millwork.

- A4: features a high-quality front (A) face, but the back (4) face has imperfections, such as knots and repairs. A4 balances quality and cost. This grade is suitable for one sided applications such as drawer bottoms and cabinet backs.

- D4: This is the lowest grade in the grading system. Both front (D) and back (4) faces allow loads of defects, including large knots and open repairs. Applications include internal panels, subflooring, and packing materials.

Specialty Plywood Types

Specialty plywood refers to plywood designed for specific purposes or environments, offering properties beyond standard plywood. Some types are water-resistant, others provide extra strength, feature chemical treatments, or have multi-ply construction. The following are common specialty plywood types and their uses:

- Marine-grade plywood is waterproof, void-free plywood designed for environments with high moisture. It is water resistant, but not completely waterproof, hence it requires proper sealing and finishes. Marine grade is ideal for boats, docks, and other marine projects.

- Baltic Birch is a high-quality, multi-ply hardwood popular for its exceptional strength, stability, and smooth surface. It is commonly used for furniture, cabinetry, and high-end drawer construction.

- Pressure-treated plywood is designed for outdoor use and exposure to harsh conditions. It is treated with chemicals to resist rot, decay, insects, and moisture. Pressure-treated plywood is suitable for outdoor structures like decks, fences, and exterior walls.

How to Choose the Right Grade of Plywood by Use Case

When choosing plywood for a project, you need to balance cost, durability, and appearance. This framework is set to guide and help you select the right plywood.

- Will it be visible(Aesthetics)?. If you are working on high-end furniture, cabinetry, or anything that will be visible and touchable, you need a high-quality surface. Select Grade A face veneer for a flawless surface, or Grade B face for a cost-effective choice.

- How much strength does it need to bear? (Structural Integrity). For structural applications where the plywood will be covered, focus on strength over appearance. For load-bearing applications like shelving, flooring, or framing, opt for C-grade or stronger panels to ensure safety and stability.

- Will it be exposed to moisture? (Moisture Exposure). If the plywood will get wet or be outdoors, select CDX, marine-grade, or pressure-treated panels to resist water and prevent warping or decay.

Project Matching Table – Choose the Right Grade by Use Case

Choosing the right plywood depends on what you are building and the conditions it will face. The table below matches common projects with the suitable plywood grades to use.

| Project Type | Requirements | Grade Level |

| High-end Furniture / Cabinet Doors (Clear Finish) | Requires one flawless surface for the best appearance. | A-B, A-C |

| Bookshelves / Storage Shelves (Painted) | B-grade face offers a good painting base, C-grade back reduces cost. | B-C |

| Interior Subfloor / Roofing | Cost-effective with enough moisture resistance for construction weather conditions. | CDX |

| Garage Storage Cabinets / Workbench | Focus on function and cost, not high appearance requirements. | CDX, Sanded Pine |

| Outdoor Shed / Garden Box (Exposed to Rain) | Requires real rot and weather resistance. | Pressure-Treated, Marine Grade |

| Bathroom / Wet Area Renovation | Prevents delamination from constant moisture. | Marine Grade |

Pro Tips from the Experts (Supplementary Content)

When choosing plywood, do not base your decision solely on the grade stamp to determine if it is right for your project. Instead, inspect the panels for defects that may affect their quality and durability. Here are important things to check:

- Warp: Check the panel by laying it flat on the ground. If it is unsteady or bends, it is warped. Warped panels are hard to cut, won’t sit flush, and weaken your structure.

- Edge Voids & Core Gaps: refers to voids or empty spaces inside the panel, or near the edges. Always avoid them, because they weaken the plywood and cause uneven surfaces.

- Surface patchwork: Check for areas with different textures, colors, or visible seams. They show repairs above defects. Surface patchworks may show through paint or stain.

- Moisture-Sealed: For outdoor or high-moisture projects, ensure the plywood is moisture-sealed. This prevents warping, swelling, and delamination over time.

FAQ

What is the difference between CDX and ACX?

The difference between CDX and ACX plywood is the grade of the surface veneers, indicated by the letters. CDX has a Grade C face veneer and a Grade D back veneer. ACX has a Grade A face veneer and a Grade C back veneer. The “X” in both CDX and ACX means the type of adhesive used, which is exterior-grade adhesive.

For CDX, both face and back veneers are rough, not sanded, and have visible defects. This makes CDX a cheap choice for structural applications where appearance doesn’t matter. For example, roof decking, subflooring, and wall sheathing.

As for ACX plywood, Grade A face veneer is smooth and free of defects, while Grade C back veneer can have knots and patches. ACX is a good choice for projects where one side will be visible, such as cabinetry and furniture.

Are there 5 grades of plywood?

No, there are not exactly five grades of plywood. The main grades are A, B, C, and D, but there are other composite and specialty grades of plywood.

Composite grades include different grades combined for cost and function. Common composite grades include AC, BC, CD, AD, and BD. The first letter represents face veneer, the second letter shows back veneer.

Specialty grades are designed for specific purposes or environments. Specialty grades include Marine-grade, Baltic birch, and Pressure-treated plywood.

Is CDX waterproof?

No, CDX plywood is not waterproof. CDX is moisture-resistant and can handle temporary exposure to rain or construction humidity. But prolonged exposure to water causes the wood to swell, warp, and rot over time.

En savoir plus sur nos produits ?

Contact